Aug 4 2016

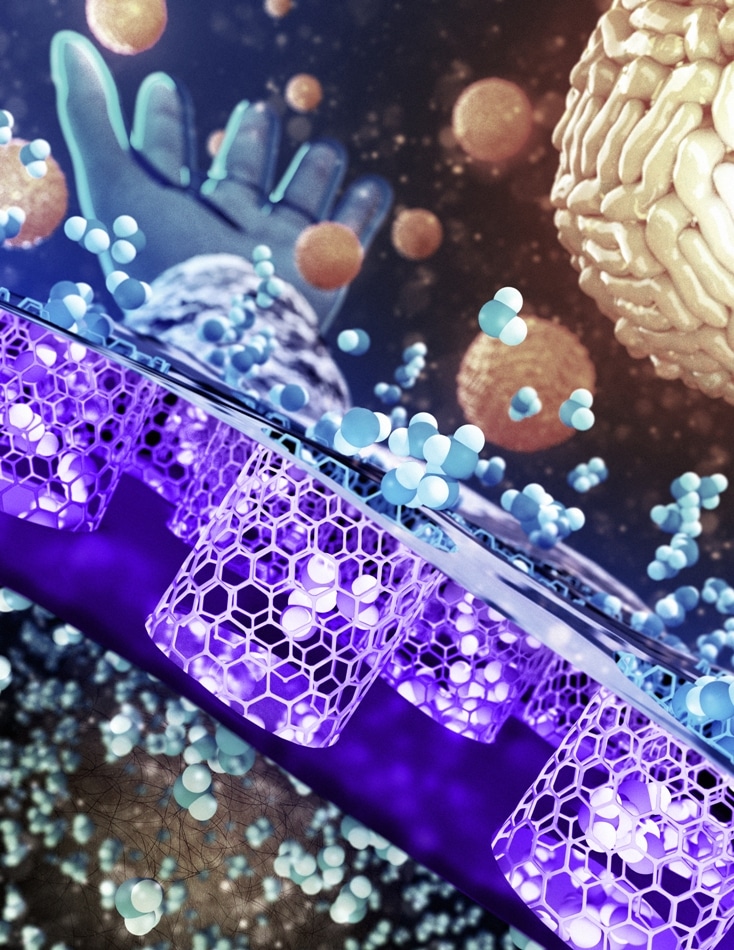

Lawrence Livermore scientists are developing a flexible membrane with sub-5 nanometer single-walled carbon nanotube pores - a key component of protective, yet breathable fabrics. (Image by Ryan Chen/LLNL).

Lawrence Livermore scientists are developing a flexible membrane with sub-5 nanometer single-walled carbon nanotube pores - a key component of protective, yet breathable fabrics. (Image by Ryan Chen/LLNL).

A highly breathable material with the ability to give protection against biological agents has been created by a group of researchers from the Lawrence Livermore National Laboratory as part of the work aiming at protecting soldiers from chemical and biological threats.

This material is regarded as the first key component of future smart uniforms, which will provide an active response to and protection against environmental chemical hazards.

The study results have been reported in the July 27 edition of the journal, Advanced Materials.

High breathability is an essential quality for protective clothing to avoid heat-stress and exhaustion when soldiers are engaged in missions in unhygienic conditions. Existing protective military uniforms are based on permeable adsorptive protective garments or heavyweight full-barrier protection, which are not able to satisfy the critical demand of providing high comfort and protection simultaneously. They provide a passive response to an environmental threat.

Breathable 'Second Skin' for Smart Uniforms

Video Credit: Lawrence Livermore National Labratory/Youtube.com

The LLNL team created flexible polymeric membranes consisting of aligned carbon nanotube (CNT) channels. These channels serve as moisture conductive pores of less than 5 nm, which are 5,000 times narrower than the width of a human hair.

We demonstrated that these membranes provide rates of water vapor transport that surpass those of commercial breathable fabrics like GoreTex, even though the CNT pores are only a few nanometers wide.

Ngoc Bui, LLNL

The unique transport properties of CNT pores impart the high breathability to the new composite material. The researchers measured the membrane permeability to water vapor and discovered that CNT nanochannels are able to sustain gas-transport rates above that of an established diffusion theory by more than one order of magnitude when the driving force is concentration gradient.

With a pore size of below 5 nm, these membranes can also offer protection against biological agents as biological threats such as viruses and bacteria typically have a size of more than 10nm. Filtration tests revealed that Dengue virus was repelled by the CNT membranes from aqueous solutions.

This finding confirms the ability of the LLNL-developed CNT membranes to provide bio-protection by size exclusion instead of by preventing wetting. The results demonstrated that the CNT pores have high breathability and bio-protection capabilities in a single functional material.

However, the size of chemicals agents are very small, so the membrane pores must have the ability to react to block the chemical threats. To achieve this, the CNT membranes were encoded with a smart and dynamic response to small chemical threats by surface modifying them with chemical-threat-responsive functional groups.

The chemical threats are detected and blocked by these functional groups by serving as gatekeepers on the pore entrance. LLNL scientists and collaborators are also involved in the development of a second response scheme, which allows the fabric to exfoliate when reacted with the chemical agent like a living skin that peels off when exposed to dangerous external factors.

The material will be like a smart second skin that responds to the environment. In this way, the fabric will be able to block chemical agents such as sulfur mustard (blister agent), GD and VX nerve agents, toxins such as staphylococcal enterotoxin and biological spores such as anthrax.

Kuang Jen Wu, LLNL

Current work focuses on the development of a multifunctional material that can rapidly transform from the breathable state to the protective state.

"These responsive membranes are expected to be particularly effective in mitigating a physiological burden because a less breathable but protective state can be actuated locally and only when needed," said Francesco Fornasiero, LLNL's principal investigator of the project.

The new uniforms are expected to be used in the field within a decade.

The goal of this science and technology program is to develop a focused, innovative technological solution for future chemical biological defense protective clothing. Swatch-level evaluations will occur in early 2018 to demonstrate the concept of 'second skin', a major milestone that is a key step in the maturation of this technology.

Tracee Whitfield, Dynamic Multifunctional Material for a Second Skin Program

The Chemical and Biological Technologies Department of the Defense Threat Reduction Agency (DTRA) in the "Dynamic Multifunctional Materials for a Second Skin D[MS]2" program, and the Laboratory Directed Research and Development (LDRD) program has funded the research work.

Other scientists contributing to this study are Eric Meshot, José Pena, Sangil Kim and Phillip Gibson (Natick Soldier Research Development and Engineering Center).