Sep 12 2016

A University of Pittsburgh and Carnegie Mellon University research team was awarded $750,000 in back-to-back grants from the Engineering Directorate of the National Science Foundation to study how novel polymers can react to heat and light, creating the potential for self-powered robotic devices.

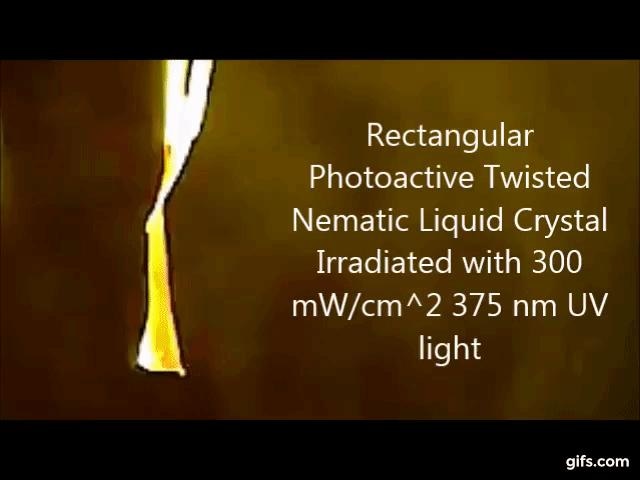

A photoactive polymer bends and twists when exposed to UV light. The ability to exploit mechanical instabilities in light-responsive polymers could enable the creation of light-operated microbots. (CREDIT: M. Ravi Shankar)

A photoactive polymer bends and twists when exposed to UV light. The ability to exploit mechanical instabilities in light-responsive polymers could enable the creation of light-operated microbots. (CREDIT: M. Ravi Shankar)

The first project supported by the Mechanics of Materials and Structures Program - " Collaborative Research: Using Boundaries to Create and Control Pathways for Photomechanical Actuation" - will focus on using materials that change shape when exposed to light. In a class of polymers custom-designed at Pitt, light drives structural transformation to generate mechanical work via Photomechanical Actuation.

"Devices made of these materials can be operated remotely without the need of wiring, circuitry or mechanical contacts," said Ravi Shankar, associate professor of industrial engineering at Pitt's Swanson School of Engineering. "Currently, the mechanical force generated by these materials is small and the shape change is difficult to control. We will work to develop new mechanisms to generate fast response times and significant amount of force. Potential applications are diverse and may include light-operated microsurgical tools, display technologies integrated with touch feedback and robotics that harness light for manipulation."

Shankar will lead the experimental work in collaboration with Kaushik Dayal, professor of civil engineering at Carnegie Mellon University, who will develop the theoretical models.

This team will also work on the second project - " GOALI/Collaborative Research: Autonomous Thermomechanical Fabrication of 3D Structures using Heat-Responsive Polymers" - which will focus on self-assembly of complex structures in a hands-free manner. "Traditionally, additive, subtractive or forming processes are used to create macroscopic geometries in polymers. Here, we embed a design at the molecular level and then exposing the material to heat spontaneously generates the desired geometry. No other physical intervention is needed to manufacture the shapes, including fairly complex ones," said Shankar.

Like light, heat is another non-contact stimulus that offers applications to many technological fields. The Grant Opportunity for Academic Liaison with Industry (GOALI) award is supported by the Manufacturing Machines and Equipment program and will involve partnership with PPG Industries. The team at Pitt will develop new polymers and molecular patterning tools and collaborate with CMU to develop a new framework for self-assembly of active structures at macroscopic scales.