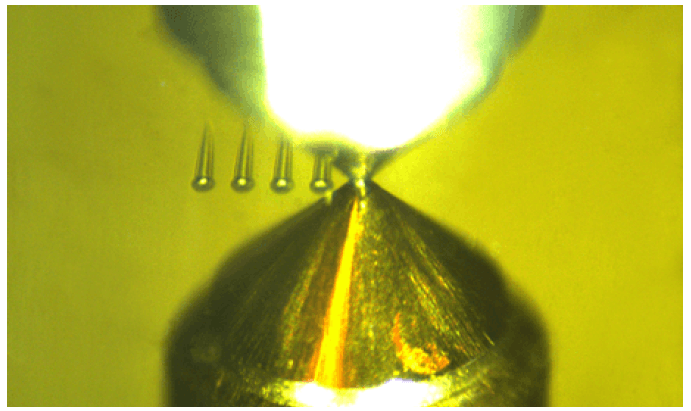

Condor Sigma shear sensor fitted with a diamond Nano Indenter tip performing scratch tests

Condor Sigma shear sensor fitted with a diamond Nano Indenter tip performing scratch tests

Driven by emerging technology and to suit customer special requirements XYZTEC Condor Sigma's comprehensive range of bond tests is always increasing. One of their latest applications made scratch testing of complex coating much easier to achieve and increased throughput by several orders of magnitude.

Condor Sigma shear sensors include a vertical force sensor that provide its unique programmable landing force feature. For scratch testing this enables the scratch force to be controlled and synchronously measured together with the horizontal shear force. This provides the control needed for scratch testing including the 3 standard procedures;

- Progressive Load Scratch Test (PLST)

- Constant Load Scratch Test (CLST)

- Multipass Scratch Test (MPST)

As with any scratch tester the quality of the bond between layers can be seen in the failure mode and force displacement graph. The following examples show the same PLST on multi layer films of different constructions.

Additional failure mode analysis such as EDX helps to show at what point layers fail. With this deeper understanding quality assurance may subsequently only require scratch testing. The Condor Sigma is a highly flexible micro materials tester specifically designed for the semiconductor and electronics industry. From its very beginning it was designed for easy and comfortable manual use, making it much faster than any dedicated scratch tester.

Its fully automatic mode delivers even more benefit. Samples are simply loaded and tested. The Sigma has fiducial mark pattern recognition to locate the samples position and then tests with precision with whatever combination of scratch tests you want. These can be different positions, procedures, directions and speeds. Being automatic, every sample is tested in exactly the same way. In a recent application, a product that required 1 day to test takes a mere 2 minutes on the Condor Sigma!