Feb 10 2017

Elastomers are used in numerous applications because of its superior material properties of resilience, elasticity, and thermal and electrical insulation. They are ideal materials for fabricating flexible electronics, smart biomedical devices, and soft robots which require soft and deformable material features in order to ensure smooth and safe interactions with humans internally and externally.

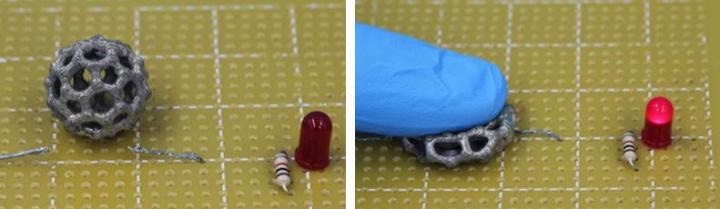

This is a 3D printed conductive buckyball that works as an electric switch. (Credit - Courtesy of Dinesh K. Patel)

This is a 3D printed conductive buckyball that works as an electric switch. (Credit - Courtesy of Dinesh K. Patel)

However, until now, the most extensively used silicon rubber-based elastomers need to undergo a thermal curing process which greatly limits its fabrication in conventional ways, namely cutting, molding and casting, which hinders geometric complexity and design freedom. To improve the design and fabrication flexibility, researchers experimented with 3D printing methods, such as the UV curing-based 3D printing methods. These methods solidify liquid polymer resins to 3D objects via patterned UV light, thereby fabricating elastomeric 3D objects. But, a majority of the commercially available UV curable 3D printable elastomers break at under 200% (two times the original length), thus rendering it incompatible for several applications.

Now, researchers have created a group of very stretchable and UV curable (SUV) elastomers. These elastomers can be stretched by up to 1100%, and are appropriate for UV curing-based 3D printing methods. This research is a joint effort between researchers from the Singapore University of Technology and Design's (SUTD) Digital Manufacturing and Design (DManD) Centre which is financially supported by the Singapore National Research Foundation (NRF), the Hebrew University of Jerusalem (HUJI), and the Campus for Research Excellence and Technological Enterprise (CREATE), which is also financially supported by the NRF. The research findings have been published in the Journal of Advanced Materials on 7 February 2017.

We have developed the most stretchable 3D printable elastomer in the world. Our new elastomers can be stretched by up to 1100% which is more than five times the elongation at break of any commercially available elastomer that is suitable for UV curing based 3D printing techniques.

Assistant Professor Qi (Kevin) Ge from the SUTD's DManD Centre, who is one of the co-leaders in creating the SUV elastomers.

High resolution 3D printing coupled with the SUV elastomer compositions enables the direct formation of hollow structures or complex 3D lattices that show very large deformation.

The new SUV elastomers enable us to directly print complicated geometric structures and devices such as a 3D soft robotic gripper within an hour. Compared to traditional molding and casting methods, using UV curing based 3D printing with the SUV elastomers significantly reduces the fabrication time from many hours, even days, to a few minutes or hours as the complicated and time-consuming fabrication steps such as mold-building, molding/demolding, and part assembly are replaced by a single 3D printing step.

Dr Ge.

The SUV elastomers sustain large elastic deformation as well as maintain superior mechanical repeatability, which makes them ideal materials for fabricating flexible electronics. To prove this, the team fabricated a 3D buckyball light switch that continues to function even after being pressed for over 1000 times.

Overall, we believe the SUV elastomers, together with the UV curing based 3D printing techniques, will significantly enhance the capability of fabricating soft and deformable 3D structures and devices including soft actuators and robots, flexible electronics, acoustic metamaterials, and many other applications.

Professor Shlomo Magdassi who is a co-leader of this project at HUJI and CREATE.