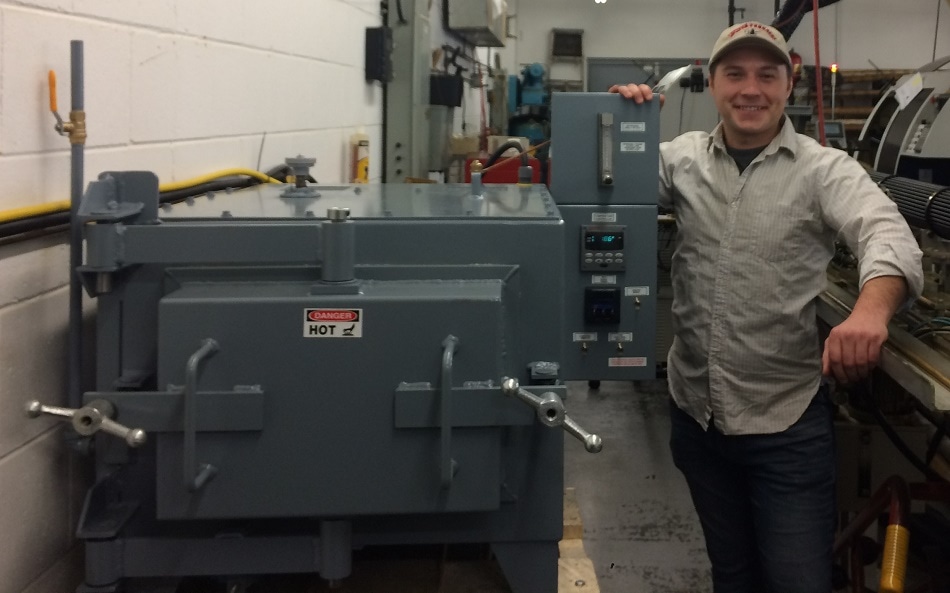

R. Hueter Co, Beverly Massachusetts, a northeast CNC machine shop specializing in male and female RF connector contact production has added a Lucifer Furnaces’ heat treating oven to meet their growing heat treating needs.

Adam Hueter, Operations Manager, chose Lucifer Furnaces because of their reputation for delivering high quality products at an affordable price. Model 42GT-H12 was customized as a bench top unit. With a chamber size of 9” x 12” x 12”, this oven is insulated with 5” of both insulating firebrick and mineral wool backup.

4 KW power allows fast heat up to 1200°F. GT ovens, built for operation using inert atmosphere, are crafted with a continuously welded outer steel shell and gasketed roof plate. A strong seal on the double pivot door is achieved with a square gasket around the door perimeter to form a tight seal to the oven face-place.

Swing bolts with T handles make clamping easy. The stainless-steel liner baffles the work chamber from the side wall heating elements and directs the air flow horizontally through the chamber for uniform heating. Hueter choose a Honeywell DC2500 temperature controller with a Soak Timer to shut off heating elements at the end of a programmed cycle in addition to a Flowmeter mounted and piped to the oven for easy connection their atmosphere supply.

Hueter plans to use the furnace primarily around 600°F for 2 hr cycles to achieve a specific Rockwell hardness with small lots of Becu pins under a nitrogen atmosphere to reduce surface oxidation in order to achieve a scale free, bright finish.

After installation, Adam notes “Right now the oven is running like a dream! I am completely satisfied with my Lucifer Oven and your team has given me great support along the way.”