Mar 30 2017

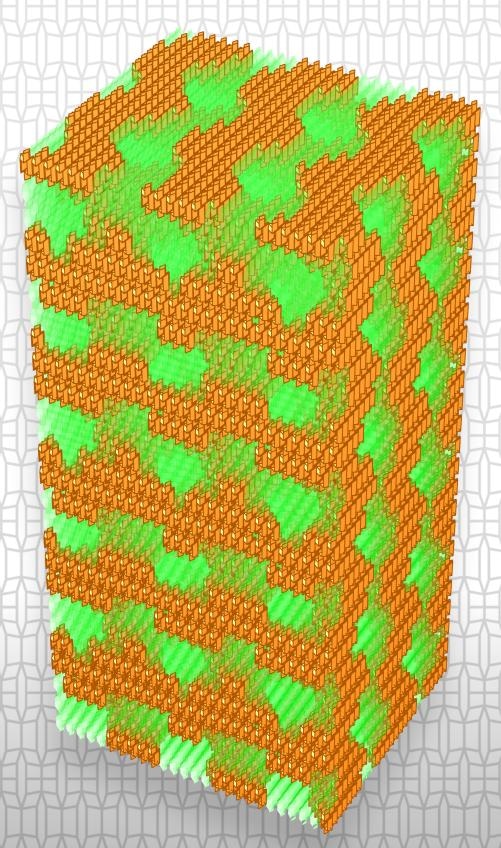

This image shows how two types of origami-inspired materials can be woven into a single structure. The orange and (semi-transparent) green portions each have their own distinct properties and allow the composite to exhibit unique behavior not possible with just the one type of building-blocks.(Credit: Nan Yang, Jesse L. Silverberg.)

This image shows how two types of origami-inspired materials can be woven into a single structure. The orange and (semi-transparent) green portions each have their own distinct properties and allow the composite to exhibit unique behavior not possible with just the one type of building-blocks.(Credit: Nan Yang, Jesse L. Silverberg.)

Researchers from Tianjin University of Technology and Harvard University have borrowed the idea of assembling building-blocks from playing with Legos to make next-generation materials a real possibility.

Nan Yang, from the Laboratory for the Design and Intelligent Control of Advanced Mechatronical Systems, and Jesse Silverberg, from the Wyss Institute for Biologically Inspired Engineering, have managed to remove a major bottleneck that was slowing down the translation of scientific advancement into commercial applications. The details of their work were published online in the journal Proceedings of the National Academy of Sciences on March, 20.

Metamaterials are driving a revolution in material science. The current approach of building every-day stuff turns out to be limited because the materials we work with have a relatively narrow range of properties and capabilities.

Jesse Silverberg, Wyss Institute for Biologically Inspired Engineering

Metamaterials surpass what is found in nature by assembling basic elements into repeating patterns. At large scales, these smaller parts impact the larger construction in unfamiliar ways. Yang noted "The variety of applications is growing. Today we see mechanical metamaterials used to shape the flow of vibrational waves like earthquakes to protect buildings. Tomorrow, who knows what will be next."

The team, however, were troubled that these discoveries have not quickly transitioned from the lab to the market. A challenge they observed was the time and effort of designing for real-world applications.

Some years ago, origami - the art of paper-folding - was well-known for its ability to quickly convert flat sheets into 3D patterns with uncommon metamaterial properties.

While easy to fold, the time required to find good designs for practical problems is often too costly. Suppose you wanted a mechanical metamaterial to absorb impact during a car crash. What's the best design for that? And even if you find a good folding pattern, does it even fit with the car's chassis?

Jesse Silverberg, Wyss Institute for Biologically Inspired Engineering

Yang and Silverberg have young children. They illustrated their 'ah-ha' moment like this: "We were working late one night over Skype and we realized the solution was literally on the floor in front of us. What if we could build metamaterials like our kids build with Legos?"

This understanding helped the researchers to design a basic set of building-blocks. After designing, the team was able to build larger and more intricate structures in the same manner their children created multi-colored robots and ships.

We started designing a basic unit, kind of like the classic 2-by-4 Lego brick, but instead of making them in different colors, we gave them different mechanical properties. A stiff one, a soft one, etc.

Jesse Silverberg, Wyss Institute for Biologically Inspired Engineering

The researchers demonstrated how to assemble two different types of mechanical ‘cloaking materials’ as examples. They also gave instances of how a pre-determined set of properties can be engineered into random 3D structures, a very abstract challenge since the start of metamaterial research.

Yang went on, "Now that have a basic strategy, we're working out the design for even more 'bricks' and methods to rapidly assemble them." Silverberg added, "Looking ahead, we foresee tools that allow anyone with a computer to easily design complex metamaterials."