Image Credits: Hosokawa Micron Ltd

Image Credits: Hosokawa Micron Ltd

Delivering high speed, continuous production of agrochemicals with good flow properties, long shelf life and good dispersibility and wettability the Hosokawa Micron agglomerator/humidifier system is becoming increasingly popular with producers of agrochemicals.

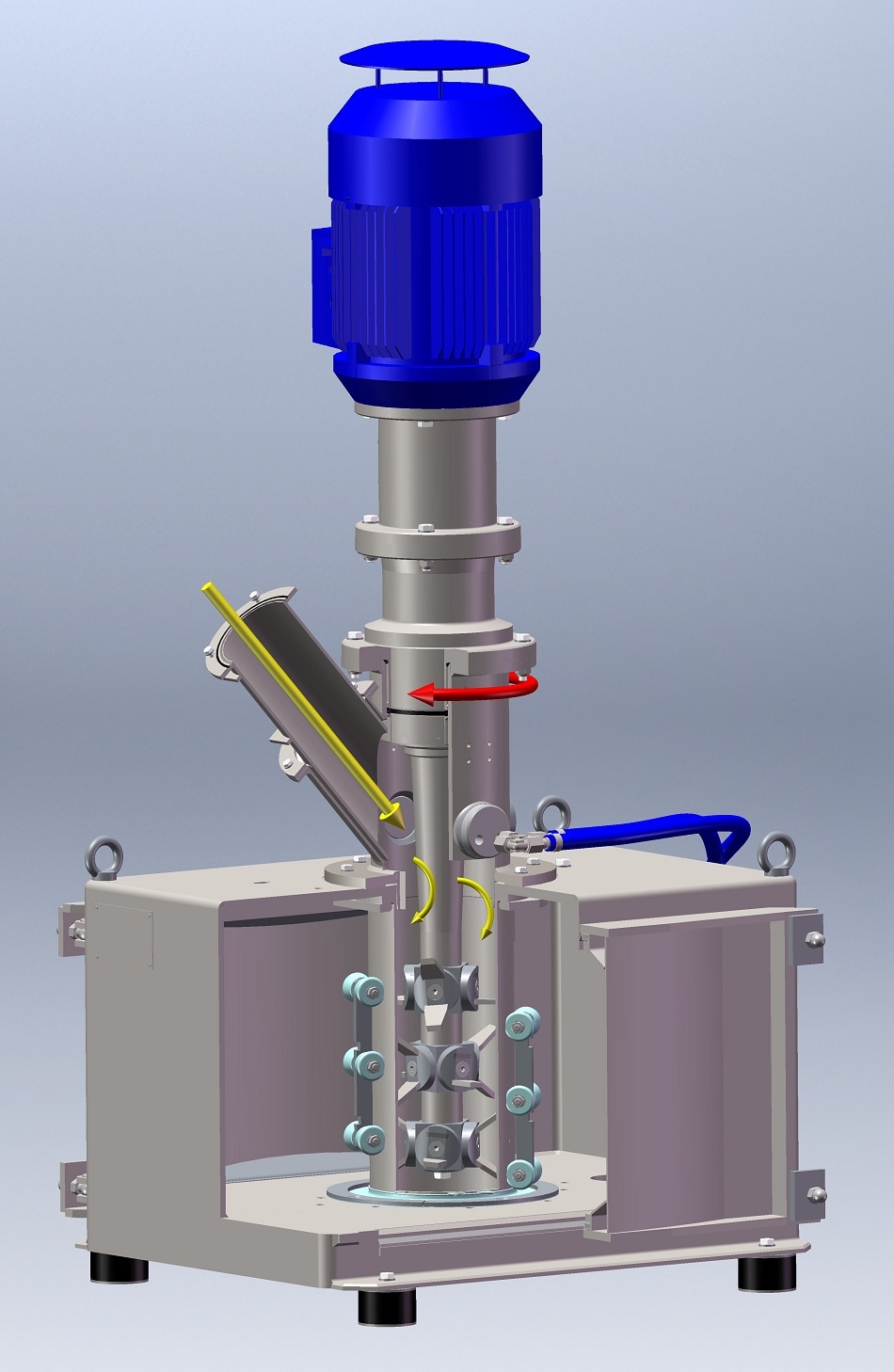

At the heart of the system is the Hosokawa Flexomix, mixer agglomerator a high speed, continuous instant mixing unit which ensures very even, homogenous humidification of the particles.

Pesticides are produced either as dry agglomerates or as dry, extruded product, having the appearance of either small cylindrical shaped pellets or spheronised round particles. The agglomerates are produced by thoroughly mixing a micronized, powdery premix with a liquid binder, such that the particles will stick to each other to form larger particles.

For both agglomeration and extrusion process, The Hosokawa Flexomix is suitable for agglomeration and extrusion production processes.

Agglomerated Product:

In case of agglomeration, the homogeneous mixing in the Flexomix ensures efficient formation of agglomerates with uniform quality, resulting in a high process yield. These agglomerates are porous and slightly irregularly shaped ensuring a good wettability and dispersibility.

The Flexomix has a self-cleaning mixing chamber, which minimizes adherence of moist product to the mixing chamber wall, allowing a relatively high liquid addition ratio as required.

The agglomerates formed in the Flexomix fall from the Flexomix into a Fluidized Bed Dryer and are dried to the required final moisture content.

Extruded Product:

In case of extrusion, the feed product is evenly humidified in a Flexomix prior to extrusion. This is carried out using a low-pressure extruder, such as a Bextruder, basket extruder which passes an extrudable mass through a perforated orifice plate. The low pressure in which this extrusion takes place ensures that the extrudates remain relatively porous, maintaining the required good dispersibility. A humidified feed product with very homogeneous moisture content is essential to achieve optimum extrusion results with a maximum yield and minimum of clogging of the extruder.

In new plants, the Flexomix is the equipment of choice for both a direct agglomeration process as well as the wetting / humidification step in case of an extrusion process to ensure a maximum extrusion performance.

In a lot of cases, the installation of the Flexomix in existing plants to replace existing (less effective) agglomeration or humidification devices has also proven to be very successful to significantly increase the yield and reduce the down time due to e.g. clogging to a minimum.

The Flexomix is used for this application by major water dispersible, granular crop protection agent producers, world wide.