Jul 31 2017

Taking inspiration from nature, KAUST Researchers have developed an economical green method that would allow common materials to repel liquid. This could lead to varied applications from underwater drag reduction to antifouling1.

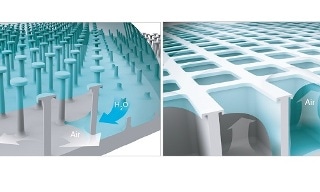

Wetting surfaces with micropillars (left) lose their omniphobicity when damaged, while microtextures with doubly reentrant cavities (right) exhibit omniphobicity despite localized damage. (Reproduced with permission from ref 1.© 2017 American Chemical Society. Created by Ivan Gromicho © 2017 KAUST)

Wetting surfaces with micropillars (left) lose their omniphobicity when damaged, while microtextures with doubly reentrant cavities (right) exhibit omniphobicity despite localized damage. (Reproduced with permission from ref 1.© 2017 American Chemical Society. Created by Ivan Gromicho © 2017 KAUST)

Omniphobicity, defined as making surfaces liquid repellent, is used in several industrial processes from minimizing bio-fouling and underwater drag to waterproofing, membrane distillation and oil-water separation.

Creating such a veneer normally relies on applying perfluorinated coatings; however, these degrade under extreme chemical and physical environments, raising costs and both health and environmental impacts and limiting their use.

Rendering conventional materials, such as metals and plastics, omniphobic has been an alluring goal for quite a while; this challenge led Himanshu Mishra and colleagues from the KAUST Water Desalination and Reuse Center to draw inspiration from nature.

Initially, the Researchers tested microtextures made up of doubly reentrant pillars: they were inspired by a US based research team who, in 2014, showed that these pillars displayed exceptional omniphobicity in air, even when the materials were inherently wetting.

At first, these results seemed to defy conventional wisdom as roughening intrinsically wetting surfaces makes them even more wetting. So we decided to investigate these microtextures for ourselves.

Himanshu Mishra, KAUST Water Desalination and Reuse Center

The team established that intrinsically wetting surfaces with doubly reentrant micropillars do truly display omniphobicity in air, but they also discovered that it was catastrophically lost in the presence of localized physical damage or defects or when soaked in wetting liquids.

These were serious limitations because real surfaces get damaged during use. This inspired us to look to nature and investigate the skins of springtails.

Himanshu Mishra, KAUST Water Desalination and Reuse Center

Skin patterns of springtails — tiny soil-dwelling insects that live in moist conditions — make the most of surface textures that possess doubly reentrant cavities, keeping them dry. By employing photolithography and dry-etching tools at the KAUST Nanofabrication Core Lab, the Researchers reconstructed these doubly reentrant microcavities on silica surfaces.

Exploiting the doubly reentrant features revealed that the microcavities captured air and prevented penetration of liquids, even under very high pressures. Furthermore, their compartmentalized nature prevented any loss of omniphobicity in the presence of localized defects or damage, or when immersed in wetting liquids.

Having demonstrated the proof of concept, we now plan to translate the fabrication process from the lab to the Workshop Core Lab in KAUST to create doubly reentrant cavities on common materials, such as polyethylene terephthalate and low-carbon steels. This may help to unlock their potential for applications to reduce hydrodynamic drag and antifouling.

Himanshu Mishra, KAUST Water Desalination and Reuse Center

Reference:

1Domingues, E.M., Arunachalam, S. & Mishra, H. Doubly reentrant cavities prevent catastrophic wetting transitions on intrinsically wetting surfaces. ACS Applied Materials & Interfaces 9, 21532-21538 (2017).|