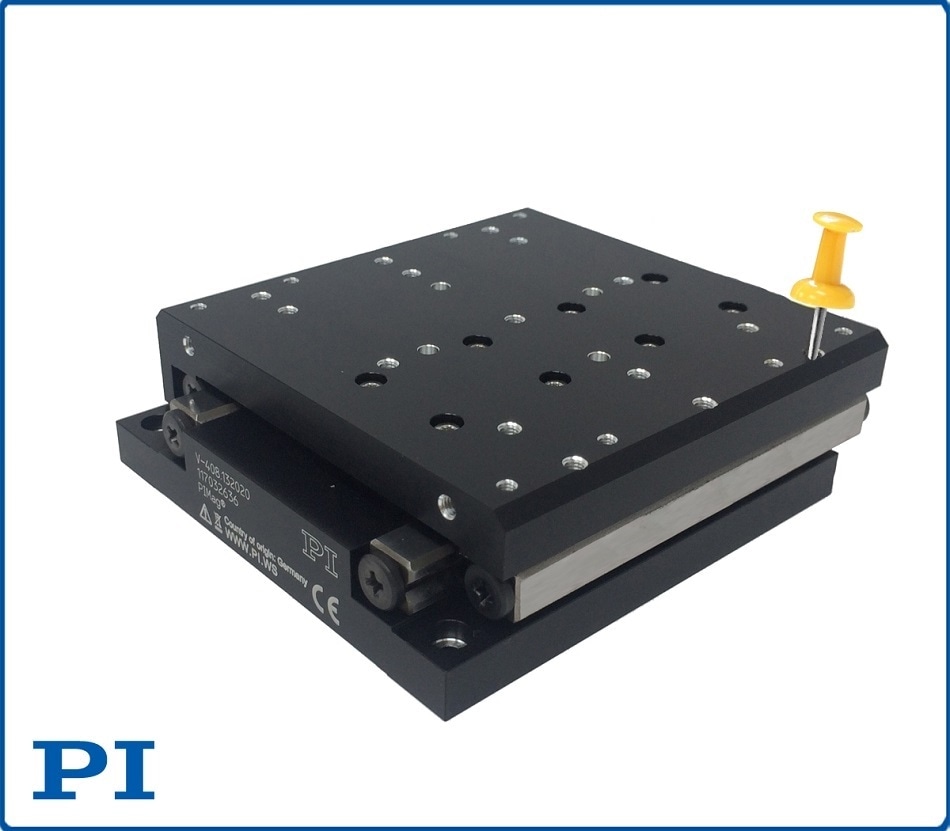

Motion and nanopositioning industry leader PI expands its PIMag® series of high dynamics linear motor stages with a new compact positioner for automation tasks. The new V-408 stage is equipped with an incremental linear encoder for direct position measurement and a high-force 3-phase linear motor drive.

High Velocity / High Duty Cycle / Low Cost

The V-408 features high load capacity precision crossed roller elements with anti-creep cage assist, preventing roller creep, and a zero-wear, non-contact linear motor – ideal prerequisites for long lifetime in high duty cycle industrial applications. The high-force linear motor achieves velocities up to 1.5m/sec. An integrated optical linear encoder provides 10 nanometers resolution. The stage achieves 20nm minimum incremental motion and excellent geometric performance with 4µm straightness and flatness.

Affordable and Compact 1” and 2” Travel Range

The V-408 is designed to keep cost of ownership and operation at a minimum. Two models are offered with 25mm and 50mm travel range. Integration is facilitated by the compact dimensions with a low profile of only 25mm. The 1” travel model features a square footprint of 80x80mm while the 2” travel model is only 25mm longer.

Why Linear Motors?

Linear motors provide very smooth motion, and a high dynamic velocity range along with rapid acceleration. They are ideal for scanning applications or automation tasks where repetitive fast start/stop motion with high precision is required and where reliability and maximum uptime are crucial.

Suitable Motion Controllers

The V-408 stage can be controlled by PI’s C-891 motion controller and also by ACS and 3rd party controllers.

Watch the Direct Drive Systems Video

https://www.youtube.com/embed/1jgp99cV1xk?rel=0&start=16

Specifications, Datasheet, More Information