Oct 26 2017

Photocathodes used in linear accelerator facilities, free electron lasers and advanced X-ray light sources generate a beam of electrons to probe matter at an atomic level. Advances in materials science have improved the composition of materials used in photocathode production that can operate at visible wavelengths and produce a beam with reduced transverse electron momentum spread.

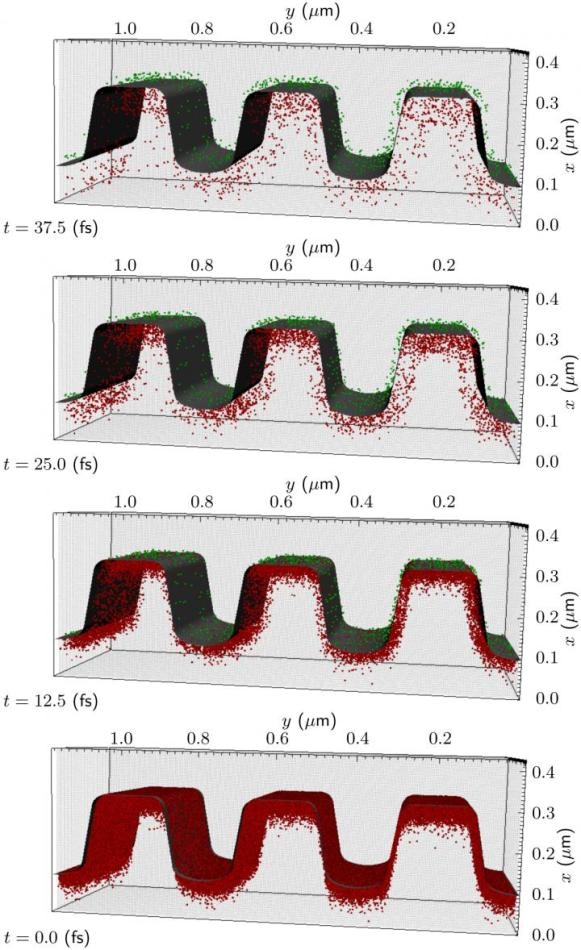

Four time snapshots from a model simulation. The simulation shows electrons (red dots) moving inside the antimony photocathode after photons are absorbed. Some electrons are emitted (green dots) from the photocathode surface while some are reflected back into the material. The number of electrons that are emitted is dependent on the applied electric field, the surface roughness of the photocathode material, and the energy of absorbed photons. (Credit: Dimitre A. Dimitrov)

Four time snapshots from a model simulation. The simulation shows electrons (red dots) moving inside the antimony photocathode after photons are absorbed. Some electrons are emitted (green dots) from the photocathode surface while some are reflected back into the material. The number of electrons that are emitted is dependent on the applied electric field, the surface roughness of the photocathode material, and the energy of absorbed photons. (Credit: Dimitre A. Dimitrov)

Despite these advances, the surface roughness of the photocathode continues to limit beam properties. A research team created computer models to bridge the gap between theoretical and experimental studies to provide a better picture of the physics at the surface of the photocathode. The results are published this week in the Journal of Applied Physics, from AIP Publishing.

A colder beam produces a brighter electron source, but surface roughness can destroy the coldness of the electron beam. Dimitre A. Dimitrov, a scientist at Tech-X Corp and one of the publication's authors, is working with others to optimize on this characteristic.

"For the first time, we can grow cathodes with specifically designed surface roughness on the experimental side," Dimitrov said. "The physics at the surface of a photocathode is incredibly complex, and we need to understand it better [to] create electron beams with optimal properties."

This work is the first time there has been a comprehensive attempt to do realistic modeling of the essential physics at the surface of the photocathode as photons are absorbed and electrons emitted. Using specialized software, the team created 3-D models that simulated electron emissions from photocathodes with flat and varied surface roughness.

The research team used the models to simulate emissions from the surface of a flat, antimony photocathode. They compared the simulations to experimental data to evaluate beam properties, including quantum yield, which quantifies the number of electrons emitted per absorbed photon, and transverse emittance, or the electron emission perpendicular to the direction of beam propagation. The team also compared simulations of antimony of known surface roughness to experimental data to evaluate the same emission properties.

"From this work, we hope to gain an understanding of how smooth surfaces have to be and over what spatial scales, to assist in the design of photocathodes for next generation ultra-bright photon and electron sources," said Howard Padmore, division deputy at Lawrence Berkeley National Laboratory.

The simulations in this study did not include the effect of variation in light on surface roughness. Future research will examine this variable to understand its effect on the distribution of loaded electrons, which could affect quantum yield. The research team, which also includes scientists from Brookhaven National Laboratory, modeled antimony in their study but they want to study other materials and compare that data to the results of their antimony study.