IPS Ceramics has announced that one of the brand new ranges currently being launched features two types of speciality cordierite ceramic.

Cordierite ceramics are well known for their exceptional resistance to thermal shock. They are often used for components that are subject to rapid thermal cycling, in applications where other ceramic materials would quickly crack or break. This can include anything from high performance kiln furniture to catalytic converter honeycombs.

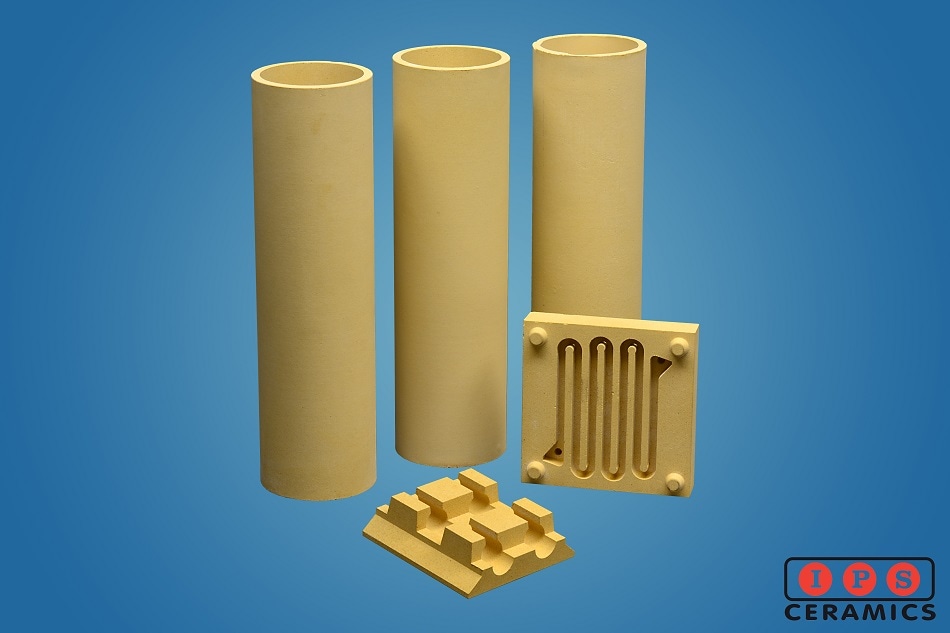

Cordierite products are fired close to 1400°C (2550°F) to give a material that is volume stable in service (temperatures up to 1300°C/2370°F). Products are thermally and electrically insulating and are often used as lead-in tubes or as supports for wire heating coils.

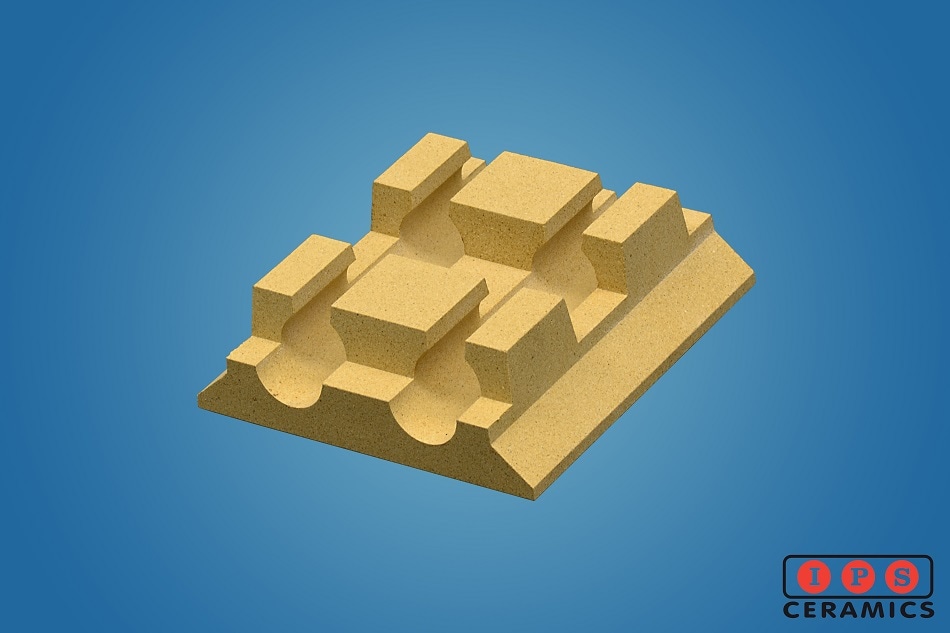

IPS offers two grades of cordierite: porous cordierite (C520) is best for thermal shock resistance and use at higher temperatures, whilst non-porous cordierite (C410) is stronger and impermeable. The manufacturing processes (extrusion, pressing and injection moulding) allow a wide variety of shapes and sizes to be produced. This offers the customer an attractive mix of design flexibility and high temperature capability.