Jan 3 2018

Interest in renewable energy is constantly increasing. Many renewables however, can be exasperatingly intermittent - when the wind stops blowing or the sun stops shining, the power drops. The fluctuating supply can be partially smoothed-out by energy storage during peak production hours, which brings its own challenges.

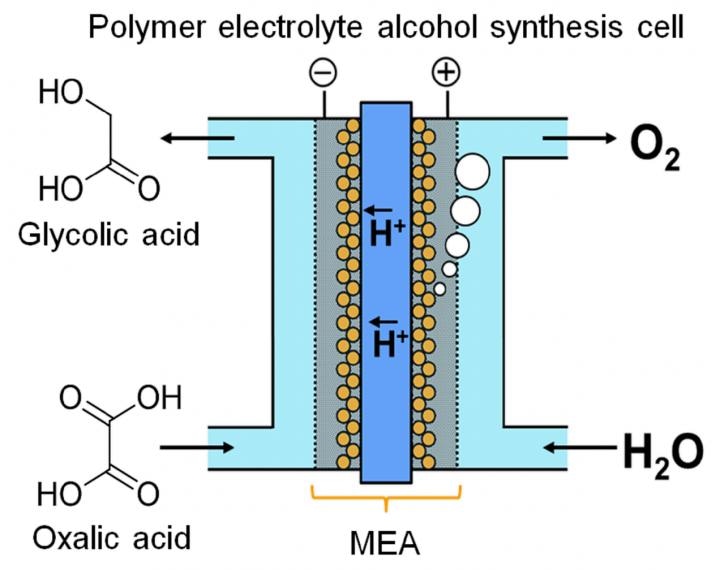

A Kyushu University research team realized continuous electrochemical synthesis of an alcoholic compound from a carboxylic acid, using a polymer electrolyte alcohol electrosynthesis cell. (Photo credit: Masaaki Sadakiyo / International Institute for Carbon-Neutral Energy Research, Kyushu University)

A Kyushu University research team realized continuous electrochemical synthesis of an alcoholic compound from a carboxylic acid, using a polymer electrolyte alcohol electrosynthesis cell. (Photo credit: Masaaki Sadakiyo / International Institute for Carbon-Neutral Energy Research, Kyushu University)

Recently, a research team at the International Institute for Carbon-Neutral Energy Research (I2CNER), within southern Japan's Kyushu University, designed a device to store energy in chemical form via continuous electrolysis.

The researchers realized that glycolic acid (GC) has a greater energy capacity than hydrogen, one of the more common energy-storage chemicals. GC can be created by four-electron reduction of oxalic acid (OX), an extensively available carboxylic acid. As illustrated in their publication in Scientific Reports, the team devised an electrolytic cell based on a unique membrane-electrode assembly. Inserted between two electrodes are an iridium oxide-based anode and a titanium dioxide (TiO2)-coated titanium (Ti) cathode, connected by a polymer membrane.

Flow-type systems are very important for energy storage with liquid-phase reaction. Most electrolyzers producing alcohols operate a batch process, which is not suitable for this purpose. In our device, by using a solid polymer electrolyte in direct contact with the electrodes, we can run the reaction as a continuous flow without addition of impurities (e.g. electrolytes). The OX solution can effectively be thought of as a flowable electron pool.

Masaaki Sadakiyo, Lead Author

Another main factor to consider is the cathode design. The cathodic reaction is catalyzed by anatase TiO2. To guarantee a solid connection between cathode and catalyst, the team "grew" TiO2 directly on Ti, in the form of a felt or mesh. Electron microscope images show the TiO2 as a wispy fuzz, adhering to the outer side of the Ti rods. In fact, its task is to catalyze the electro-reduction of OX to GC. In the meantime, at the anode, water is oxidized to oxygen.

The team discovered that the reaction was faster at higher temperatures. However, increasing the heat too much encouraged an undesirable by-process - the conversion of water to hydrogen. The perfect balance between these two effects was at 60 °C. At this temperature, the device could be additionally enhanced by decelerating the flow of reactants, while boosting the amount of surface area available for the reaction.

Fascinatingly, even the texture of the fuzzy TiO2 catalyst made a huge difference. When TiO2 was prepared as a "felt" by growing it on thinner and more tightly packed Ti rods, the reaction took place faster than on the "mesh" - perhaps because of the greater surface area. The felt also prevented hydrogen production, by blanketing the Ti surface more tightly than the mesh, preventing the exposure of bare Ti.

In the right conditions, our cell converts nearly 100% of OX, which we find very encouraging.We calculate that the maximum volumetric energy capacity of the GC solution is around 50 times that of hydrogen gas. To be clear, the energy efficiency, as opposed to capacity, still lags behind other technologies. However, this is a promising first step to a new method for storing excess current.

Miho Yamauchi, Co-Author