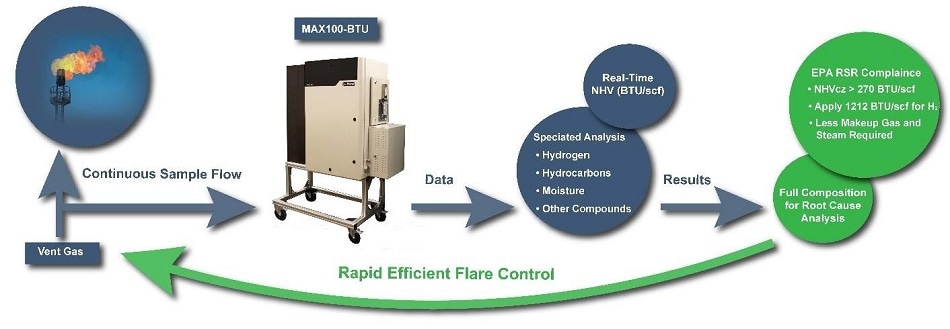

Pittsburgh, Pennsylvania, February 7, 2018 - Recent EPA updates to the Refinery Sector Rule (RSR) are designed to ensure 98% destruction efficiencies for all US refinery flares. By January of 2019, flare owners will be required to monitor the heating value of the vent gas whenever regulated material is sent to flare. The Net Heating Value (NHV) in the combustion zone must be kept above the regulatory limit of 270 BTU/scf, and operators will need to add steam or supplemental gas in real-time to remain in compliance.

The MAX100-BTU measures the full composition of the vent gas in seconds, and reports the Net Heating Value (NHV) with accuracy better than ± 1%.

The MAX100-BTU measures the full composition of the vent gas in seconds, and reports the Net Heating Value (NHV) with accuracy better than ± 1%.

Rapid, efficient flare control depends on the speed of analysis of the vent gas monitor. Online Gas Chromatographs (GCs) are commonly used to measure flare gas composition, but they take several minutes to complete the analysis. Extrel’s MAX100-BTUTM, flare gas mass spectrometer, measures the complete composition of typical refinery flare gas samples in < 20 seconds. It reports individually speciated concentrations of H2, H2S, and C1-C5+ hydrocarbons, and calculates the NHV to within ± 1%.

New EPA approvals for RSR QA Alternatives have just been published. They ensure that mass spectrometer operating and validating procedures are clearly defined for flare monitoring and compliance.