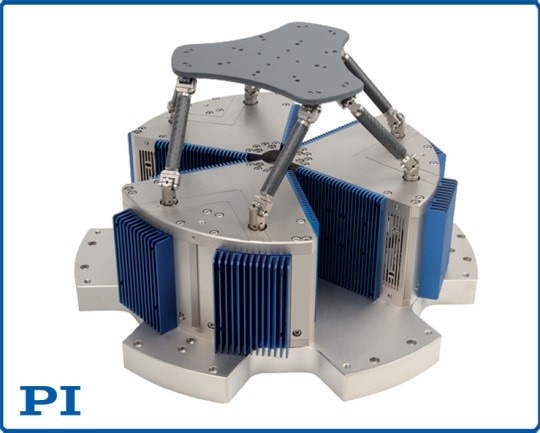

Google engineers know that a shaky hand can ruin a selfie so they designed the shake out of the Pixel 2 camera using PI’s H-860 high speed hexapod system that accurately simulates motion with 6 degrees of freedom. The high accuracy and bandwidth of the shaker hexapod is a critical tool for optimizing motion and image stabilization algorithms, such as used in drones and cameras. The result is pinpoint accurate crisp images. Renowned industry-wide for nanometer precision motion systems, PI’s family of parallel-kinematic hexapod motion systems have many applications, including vibration simulation, precision positioning, lens alignment in camera manufacturing, photonic fiber alignment and image stabilization.

Freely Defineable Trajectory and Pivot Point

The 6-axis hexapod motion system is based on parallel kinematic structure with six frictionless actuators to provide six degrees of freedom. The user-defined pivot point (center of rotation) can be changed on the fly by one software command for increased versatility. Tracking of pre-defined trajectories, sinusoidal curves, and freely definable paths with high trajectory accuracy can easily be programmed with the included software tools.

Benefits of Shaker Hexapod

The H-860 is designed to provide acceleration of 4g and velocity to 250 mm/sec– all while operating quietly. X, Y, Z travel range 15mm with incremental motion of 1µm, and up to 8° in pitch, yaw and roll (θX, θY, θZ) with 9 µrad incremental motion.

Strong and Light, Low Inertia

Extremely stiff and light-weighted carbon fiber components reduce the inertia and result in a high Eigenfrequency of 200Hz, important for fast response, high operating frequencies, and high throughput motion. The direct-drive hexapod comes with a powerful digital vector motion controller with open software architecture and hexapod-specific software.

More Hexapod Applications

Other hexapod applications may require higher load and motion ranges. PI’s family of hexapods can handle loads from 1kg to more than 2000kg for applications as diverse as fiber alignment and automotive automation.

Read Why Google Engineers can make better Cameras using PI’s Direct-Drive Hexapod Multi-Axis Motion Platform

http://www.pi-usa.us/blog/why-google-engineers-can-make-better-cameras-using-pis-direct-drive-hexapod-multi-axis-motion-platform/

Specifications, Datasheet, More Information