Master Bond EP30NS is a two component epoxy system that cures at room temperature or more rapidly at elevated temperatures. It is optically clear especially in thin sections and can be used as an adhesive, sealant, coating and encapsulation compound.

EP30NS offers dimensional stability, linear shrinkage of less than 0.01%, excellent physical strength characteristics and cures rigid. Most significantly, this epoxy system has been independently tested per ASTM D4060-14 for abrasion resistance for 1,000 cycles and exhibited a loss of weight of only 18.3 mg. This value exceeds typical epoxy compositions and demonstrates the compound’s ability to withstand exposure to scuffing, gouging, scraping, scratching and wear.

“Master Bond EP30NS has a Shore D hardness of 80-90”, says Rohit Ramnath, Senior Product Engineer. “It possesses a coefficient of thermal expansion of 30-35 x 10-6 in/in/°C and is well suited for small potting applications. Its long term electrical insulation characteristics are quite impressive. Also noteworthy is that EP30NS has a tensile strength of 9,000-11,000 psi and a refractive index of around 1.56 at 589 nm.”

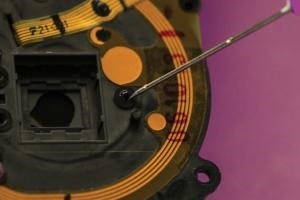

This formulation has a 4 to 1 mix ratio by weight. Working life after mixing a 100 gram batch is 20-30 minutes at 75°F. It has a mixed viscosity of 25,000-45,000 cps and flows readily. This system is available for use in ounce, ½ pint, pint, quart and gallon kits. It can also be purchased in double barrel cartridges. These cartridge containers can be dispensed using gun applicators.

Master Bond Abrasion Resistant Adhesives

Master Bond EP30NS is a rigid, optically clear, nanosilica filled epoxy system that features outstanding resistance to wear, chemical exposure and moisture. This product has high dimensional stability and outstanding dielectric properties. Read more about Master Bond’s abrasion resistant adhesives at https://www.masterbond.com/properties/abrasion-resistant-adhesives-and-coatings or contact Tech Support. Phone: +1-201-343-8983 Fax: +1-201-343-2132 Email: [email protected].