May 17 2018

The future of electronic gadgets lies partially within the “Internet of Things” - the network of devices, appliances, and vehicles fixed within electronics to facilitate connectivity and data exchange. Engineers from the University of Illinois are attempting to make this possible by reducing the size of the transformer, which is an extremely large component of integrated circuits used for wireless communication.

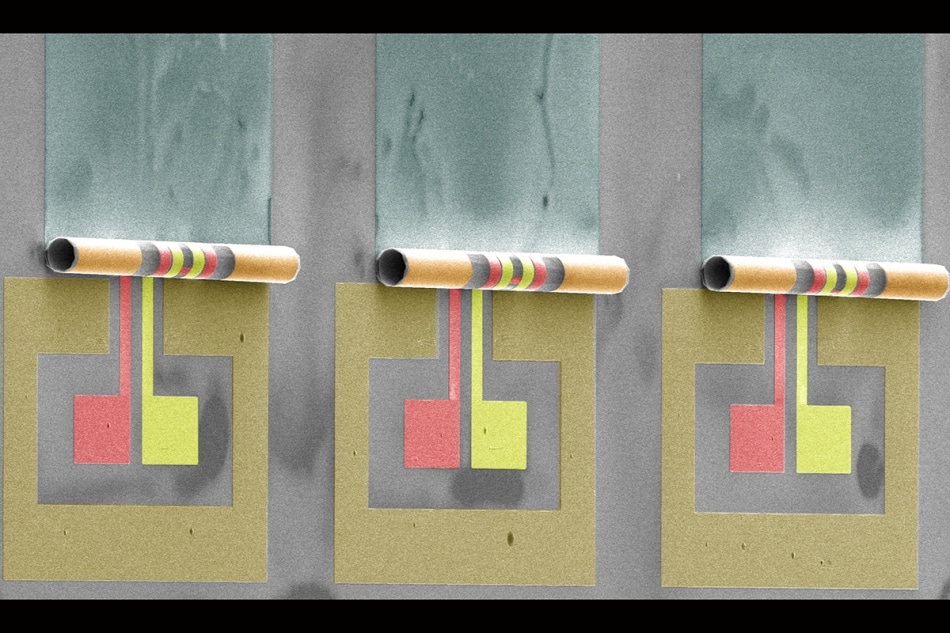

A photomicrograph of three 50-micron diameter rolled transformers developed by Illinois professor Xiuling Li’s team. (Image credit: Wen Huang)

A photomicrograph of three 50-micron diameter rolled transformers developed by Illinois professor Xiuling Li’s team. (Image credit: Wen Huang)

Compared to its 2D progenitors, three-dimensional rolled-up radio frequency transformers occupy 10 to 100 times less space, perform better when the power transfer ratio increases, and have a simpler fabrication process, according to a paper describing their design and performance in the journal Nature Electronics.

Transformers are one of the largest and heaviest elements on any circuit board. When you pick up an LED light bulb, it feels heavy for its size and that is in part because of the bulky transformer inside. The size of these transformers may become a key obstacle to overcome in the future for wireless communication and IoT.

Xiuling Li, Chief Investigator and Professor of Electrical and Computer Engineering

Transformers employ coiled wires to turn input signals into specific output signals for use in devices like microchips. In the past, researchers have built some radio frequency transformers using a stacked conducting material to solve the space issue, but these have restricted performance potential. This restricted performance is because of inefficient magnetic coupling between coils when they have a high-turns ratio, meaning that the main coil is a lot longer than the secondary coil, or vice versa, Li said. These stacked transformers have to be produced using special materials and are hard to fabricate, unbendable, and bulky - features that are far from suitable for Internet of Things devices.

The new transformer design uses methods Li's group earlier formulated for building rolled inductors. “We are making 3D structures using 2D processing,” Li said. The researchers place carefully patterned metal wires onto stretched 2D thin films. Upon releasing the tension, the 2D films self-roll into miniature tubes, allowing the main and secondary wires to coil and nest seamlessly inside each other into a much smaller area for best magnetic induction and coupling.

The nested 3D architecture results in high-turns ratio coils, Li said. “A high turns ratio transformer can be used as an impedance transformer to improve the sensitivity of extremely low power receivers, which are expected to be a key enabler for IoT wireless front ends,” said electrical and computer engineering professor and co-author Songbin Gong

Rolled transformers can also receive and convert higher frequency signals compared to the larger devices.

Wireless communication will be faster and use higher-frequency signals in the future. The current generation of radio frequency transformers simply cannot keep up with the miniaturization requirements and high-frequency operation of the future. Smaller transformers with more turns allow for better reception of faster, high-frequency wireless signals, as well as high-level integration in IoT applications.

Wen Huang, Lead Author and Postdoctoral Researcher

The new transformers have a strong fabrication process—stable beyond typical foundry temperatures and well-matched with industry-standard materials. This study made use of gold wire, but the research team has successfully shown the fabrication of their rolled devices using industry-standard copper.

The next step will be to use thinner and more-conductive metal such as graphene, allowing these devices to be made even smaller and more flexible. This advancement may make it possible for the devices to be woven into the fabrics of high-tech wearables.

Xiuling Li, Chief Investigator and Professor of Electrical and Computer Engineering

This research was supported by The U.S. Department of Energy Office of Basic Energy Science and the National Science Foundation.