May 21 2018

Traditionally, fabrics developed from silkworm fibers have been valued for their refreshing coolness and stunning luster. Now, while studying the optical properties of the cocoon fibers of the Madagascar comet moth (Argema mittrei) - the caterpillar of a wild silk moth - researchers at the Columbia University School of Engineering and Applied Science discovered that fibers created by this caterpillar are much more superior in terms of cooling ability and brilliance.

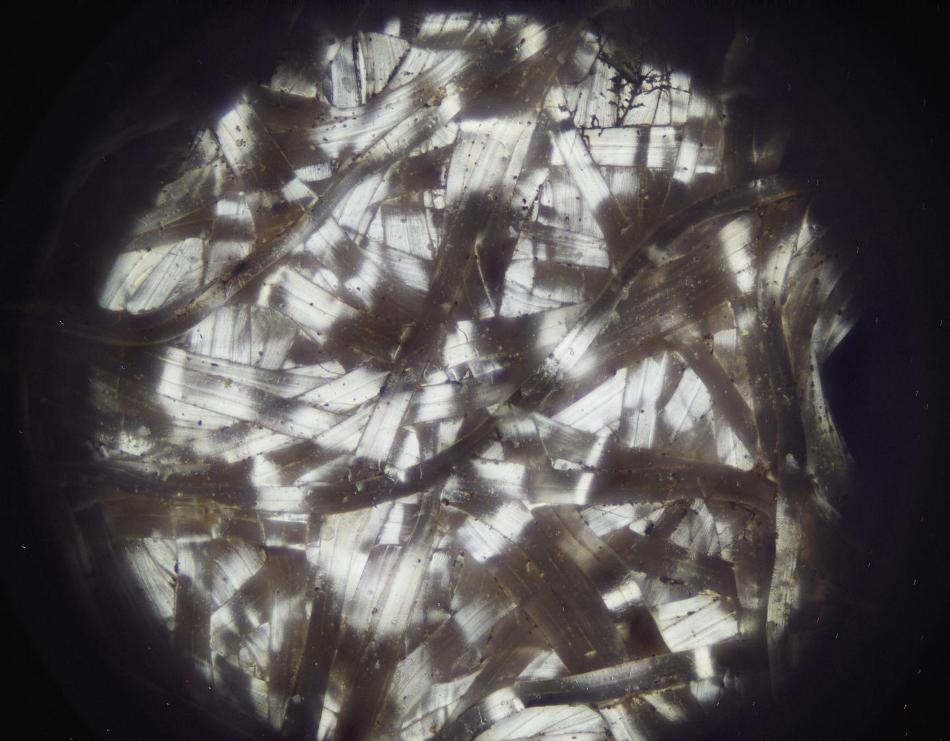

Madagascar comet moth cocoon fibers have a highly metallic sheen. (Image credit:Norman Shi and Nanfang Yu/Columbia Engineering)

Madagascar comet moth cocoon fibers have a highly metallic sheen. (Image credit:Norman Shi and Nanfang Yu/Columbia Engineering)

The cocoon fibers of the comet moth have amazing cooling properties and at the same time, they possess excellent capabilities to reflect sunlight and transmit light signals and images. After making this breakthrough discovery, the researchers developed ways to spin artificial fibers that mimic the optical properties and nanostructures of natural fibers.

The researchers, headed by Nanfang Yu, associate professor of applied physics, characterized the optical properties linked with one-dimensional nanostructures which they discovered in the cocoon fibers of the comet moth. Highly fascinated by the exceptional properties of these fibers, the team eventually developed a method to spin artificial fibers that imitate the optical properties and nanostructures of the natural fibers. The results of the study have been reported in Light: Science & Application.

The comet moth fibers are the best natural fibrous material to block sunlight we've ever seen. Synthesizing fibers possessing similar optical properties could have important implications for the synthetic fiber industry. Another amazing property of these fibers is that they can guide light signals or even transport simple images from one end to the other end of the fiber. This means we might be able to use them as a biocompatible and bioresorbable material for optical signal and image transport in biomedical applications.

Nanfang Yu, Nanophotonics Expert

Although domesticated silkworms produce individual fibers that appear to be transparent, solid cylinders under an optical microscope, the separate thread spun by the comet moth caterpillars exhibit a highly metallic sheen. A high density of nanoscale filamentary air voids is present in the comet moth fibers, and these air voids run along the fibers and cause powerful specular (mirror-like) reflection of light. Over 70% of visible light is reflected by a single fiber with the thickness of a single strand of human hair, approximately 50 microns in diameter.

However, in the case of common textiles, such as silk fabrics, this level of reflectivity can only be reached by putting together numerous layers of transparent fibers to achieve an overall thickness of roughly 10 times that of one comet moth fiber. Moreover, the high reflectivity of comet moth fibers goes much further than the visible range into the infrared spectrum, which cannot be seen by the human eye but contains around 50% of the solar power. This, along with the ability of the fibers to absorb ultraviolet (UV) light, makes them perfect for blocking sunlight, which contains infrared, UV, and visible components.

Transverse Anderson localization refers to the ability of comet moth fibers to guide light, and this effect is the outcome of the filamentary air voids along the fibers: powerful optical scattering in the fiber cross-section is caused by the air voids. While this provides sideways confinement of light, it does not present any obstacle for the propagation of light along the fibers.

This form of light guiding - confining light to propagate within the interior of a strand of material with no sideways light leakage--is very different from the one utilized in light transmission through undersea fiber-optic cables, where light confinement is provided by reflection at the boundary between a fiber core and a cladding layer. This is the first time transverse Anderson localization has been discovered in a natural materials system. Our finding opens up potential applications in light guiding, image transport, and light focusing where biocompatibility is required.

Norman Shi, Lead Author & PhD Student

After characterizing the comet moth fibers, Yu's team went on to develop new fiber pulling techniques that mimic the comet moth’s fiber spinning mechanism to produce fibers integrated with a high density of filamentary or particulate voids. A density of voids that are several times higher than that found in the natural fibers was achieved by the researchers: a single bioinspired fiber is capable of reflecting about 93% of sunlight. To create these bioinspired fibers, the researchers used two materials— a synthetic polymer (polyvinylidene difluoride) and a natural material (regenerated silk, i.e., a liquid precursor of silk fibers). While the former can be used for high throughput production, the latter can be used for applications demanding biocompatibility.

The single major difference between our bioinspired fibers and fibers used universally for textiles and apparel is that the bioinspired fibers contain engineered nanostructures, whereas conventional fibers all have a solid core. The capability of structural engineering on the tiny cross-section of a fiber via a high-throughput, high-yield fiber spinning process opens up a new dimension of design -we can infuse completely novel optical and thermodynamic functions into fibers and textiles composed of such fibers. We could transform the synthetic fiber industry!

Nanfang Yu, Nanophotonics Expert

Potential applications for these bioinspired fibers include the production of ultra-thin summer clothing that contains "air conditioning" properties. Only a few layers of the fibers would be required to develop a fully opaque textile that is just a fraction of a paper sheet in thickness. However, when the wearer sweats, it would not become translucent, which is a usual problem associated with traditional textiles. Though sweat reduces the number of fiber-air interfaces that reflect light to reduce the opaqueness of common fabrics, it will not impact the nanoscale air voids that are integrated into the bioinspired fibers.

Furthermore, cooling would be promoted by ultra-thin clothing made of the "porous" fibers through a combination of air flow between the exterior and the microenvironment of the human body, sweat evaporation, and radiation of body heat to the outside environment. "Thus, your clothes could give you the ultimate cooling experience through the collective effect of evaporative, convective, and radiative cooling," added Yu.

As one of the largest in the world, the Madagascar comet moths have cocoons that span 6 to 10 cm in length. These caterpillars make their cocoons in Madagascar’s tree canopy, with sufficient amount of sunlight. It is the reflective metallic sheen of their cocoons that prevents overheating of the pupae from the harsh sunlight. Catherine Craig, director of the NGO Conservation through Poverty Alleviation, International (CPALI), brought these incredible fibers to Yu's attention. The filamentary air voids of these fibers could be the outcome of natural selection to avoid overheating.

By working with rural farmers in Madagascar, CPALI develops sustainable livelihoods that support both ecosystems and people by cultivating and selling native resources. The fibers created by the caterpillars of the comet moth are one such product.

Presently, Yu is exploring ways to boost the throughput of creating such bioinspired nanostructured fibers. Yu’s laboratory wants to realize this feat without making any major changes to the standard practice of industrial fiber pulling.

"We don't want to drastically change those gigantic fiber spinning machines in use throughout the industry," said Yu. "Instead we want to introduce clever twists to a few critical steps or components so these machines can produce nanostructured, rather than solid, fibers."