Electro Scan Inc., a leading provider of intelligent leak detection technologies and cloud-based software-as-a-service (SaaS) analytics, today announced that its Founder & Chairman, Chuck Hansen, will present at the 2018 COMSOL Conference in Boston, Massachusetts, October 3-5, 2018.

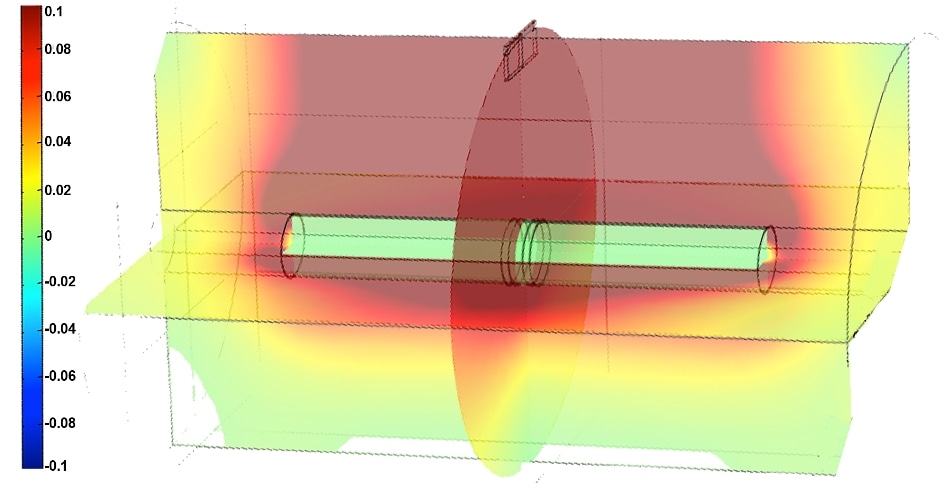

Electro Scan Inc. COMSOL® Multiphysics® Focused Electrode Leak Location (FELL) Pipeline Diagnostic Tool. (Graphic: Business Wire)

Electro Scan Inc. COMSOL® Multiphysics® Focused Electrode Leak Location (FELL) Pipeline Diagnostic Tool. (Graphic: Business Wire)

Electro Scan’s patented and patent-pending low voltage conductivity technology is seen as a revolutionary technology that directly benefits municipal sewer and water pipeline owners engaged in rehabilitation and replacement programs.

Recently, the American Water Works Association (AWWA) issued its 2018 State of the Water Industry Report naming “Renewal and Replacement of Water and Wastewater Infrastructure” as the industry’s #1 priority for the fourth year in a row. Yet, the absence of technologies to reliably certify repairs as watertight can challenge the long-term sustainability and resiliency of infrastructure replacement programs.

The Company’s focused electrode leak location (FELL) technology is singularly unique in its ability to provide precise, unbiased, and unambiguous leak testing results and certification of new and rehabilitated pipes as watertight, especially after service reconnection.

Once a test is completed in the field, results are available within minutes, without requiring third-party data interpretation.

As a result, owners and contractors can immediately diagnose and prioritize repairs, which is especially advantageous to owners before accepting new pipe installations and authorizing contractor payment.

“It is a privilege to be selected by such an esteemed committee of expert COMSOL® users,” stated Hansen.

According to USEPA, each year more than 860 billion gallons of wastewater contaminate rivers and streams used for public drinking water, with 2.2 billion gallons of treated drinking water lost each year. These avoidable losses result from cracks, bad service connections, defective joints, contractor damage, poor construction, and structural failures. In many cases, leaks are unable to be located precisely, nor able to be quantified using currently-available inspection technologies.

Hansen’s paper, entitled “Using Multiphysics to Quantify Leakage Rates in New and Rehabilitated Sewer and Water Pipes”, will be presented on Thursday, October 4, following Hansen’s appearance at the 91st Annual Water Environment Federations Annual Technical Exhibition & Conference (WEFTEC) 2018 in New Orleans, Louisiana, September 29 – October 3, 2018.

The Company’s FELL technology certifies pipes as watertight, in accordance with ASTM Standard F2550 – just renewed through December 31, 2026 – replacing less accurate acoustic, visual, and closed-circuit television (CCTV) camera-based inspection devices.

Encouraged by renowned civil engineering educator Ken Kerri, Ph.D., P.E., Program Director, Office of Water Programs, California State University, Sacramento, Electro Scan’s technology reliably tests & certifies Cured-In-Place Pipe (CIPP) installations and Spray-In-Place Pipe (SIPP) coatings.

To help prepare for field testing, Hansen selected COMSOL® Multiphysics® for quantitative analysis, replicating results at dozens of utilities in the U.S. and leading international water utilities for assessing pre- and post-rehabilitated sewer and water pipelines.

For more than 25 years, sewer & water rehabilitation contractors and suppliers have relied exclusively on visual inspection or CCTV inspection to evaluate the water tightness of existing or rehabilitated pipelines.

Since 2011, municipal sewer and water system owners have seen FELL technology consistently locate and quantify leaks in pipes that had been previously certified as watertight.

In addition to locating leaks within 3/8th of an inch (1cm), Electro Scan’s technology quantifies leakage rates for each defect in customary units of gallons per minute or liters per second.

Similar to using low voltage current in well-known holiday testing techniques for protective coatings, the Company is able to test 360-degrees of a pipe wall and along its entire length.

“We are delighted to collaborate with so many leading cities, municipal utilities and consulting engineers, adopting more stringent acceptance standards for assessing new and existing pipelines, bringing a direct cost saving to rate payers and municipal bondholders,” stated Hansen.

“Given the nearly $1 trillion needed to upgrade sewer and water infrastructure, the industry needed an independent and reliable tool to make sure pipeline owners prioritize the right pipes to be fixed, and then certified as watertight,” added Hansen.

In addition to using COMSOL® Multiphysics® to help validate its capabilities, the Company has undergone independent testing by the U.S. Environmental Protection Agency (USEPA), Water Research Foundation (WRF), university testing, and customer benchmark tests compared to results from legacy inspection devices.

Validation testing was conducted on various pipe materials, sizes, lengths, depth of cover, soil types, and lining materials, including both live pipelines and exhumed pipe sections.

Since 2015, WRc plc of Swindon, England has adopted Electro Scan’s technology for its exclusive use in leak location/quantification in the UK.

A limited number of users were invited to present at the 2018 COMSOL Conference in Boston, with abstracts reviewed by a 55-person Selection Committee with representatives from 13 countries.

“Disruptive technologies, like Electro Scan, take the guesswork out of decision-making needed to ensure reliability, resiliency, and sustainability of our valuable water infrastructure,” continued Hansen.

Equipment is offered for licensing to municipal utilities and authorized contractors, with services available from Electro Scan Inc. or an authorized agent.