A Letchworth prototyping company has helped a group of students reach the final stages of a major international aerospace competition.

Ogle Models was asked to work with a team from University College London (UCL) to create a prototype for the Unmanned Aircraft Systems Challenge designed to develop and inspire the next generation of engineers.

The UCL team was asked to design, manufacture and operate an unmanned aircraft which was capable of completing a range of tasks simulating a humanitarian mission.

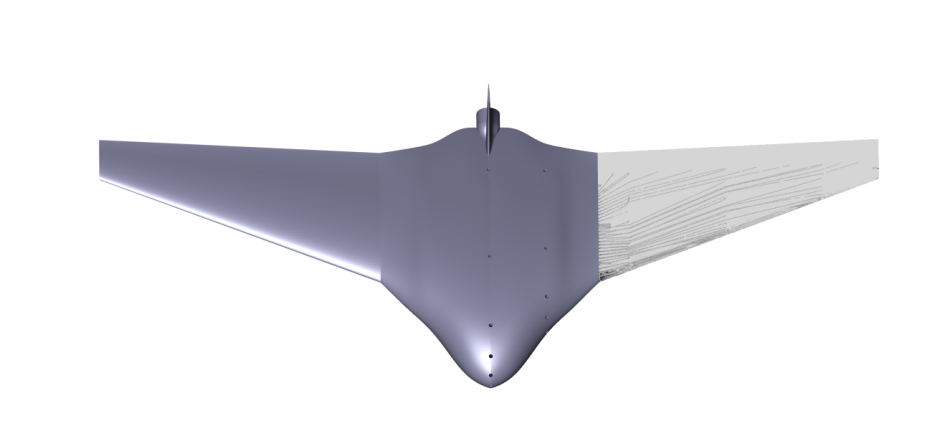

Rising to the challenge, they developed a tail-less, blended-wing body aircraft, which was to be made from carbon-fibre reinforced polymer. However, when it came to making the actual model the team realised there were issues.

To develop a model capable of enduring wind tunnel testing is often expensive, especially if the specific part requires pressure taps essential to sampling the distribution of air across the prototype. It was when attempting to solve this issue that the expertise of Ogle was sought.

Sam Hiscox, team leader for the project, said: “Following the wind tunnel testing, the results converged across a range of angles of attack and yaw positions. Pressure plots taken from the taps validated the aerodynamic properties of the design, which would not have been possible without Ogle’s expertise.

“With the computational fluid dynamics (CFD) simulations validated, the team received their design report, for innovative use of materials and manufacturing techniques in creating a wind tunnel model.

“Ogle’s support of university projects is indicative of their forward-thinking outlook and investment in the people of the future.”

Ogle recommended using Stereolithography (SLA), a form of highly accurate 3D printing technology, which meant the pressure taps could be built within the model. This led to costs being significantly reduced.

Matt White, Senior Sales Engineer at Ogle, said: “The accuracy of industrial SLA ensured that the complex geometry of the scaled-down aerodynamic surfaces was replicated with precision. For clarity reasons, the team chose ClearVue resin, which allowed the pressure tapping pathways to be seen on the finished model.

“UCL is regarded as one of the best institutions in the country when it comes to training tomorrow’s mechanical engineers and we were only too happy to help when the team approached us.”

It is not the first time Ogle has worked with a team of students to help them compete within a high-level engineering competition. In 2016, the prototyping company has helped bring to life a unique racing car which had been designed by another UCL group entering the IMechE Formula student event.

The Unmanned Aircraft Systems Challenge is an international competition run by the prestigious Institution of Mechanical Engineers.