In this case study Techsil provided a bespoke Form-in-Place Foam Gasketing service to TRT Lighting to produce an IP rated seal for the lid of an outdoor lighting luminaire. The new process replaced a manual system of gasket application saving time and allowing vital resources to be used elsewhere.

UK based, TRT Lighting Ltd (Thorlux Road and Tunnel Lighting) designs, manufactures and supplies energy efficient, environmentally friendly lighting products for exterior lighting markets. Involved in designing lighting for civil engineering projects such as roads, tunnels, airports, urban centres and amenity lighting. They are also very active in the high demand market of outdoor HID lighting replacement and retrofitting with LED luminaires.

TRT needed to produce an exacting, inert seal on the top lid of an outdoor LED light fitting to meet IP66 requirements and lasting throughout the life of the product. The seal was being achieved by manually applying an adhesive backed pre-cut gasket on the production line. With high order demand and volumes of finished product significantly increasing, the need to expedite certain elements of the assembly process at TRT were paramount.

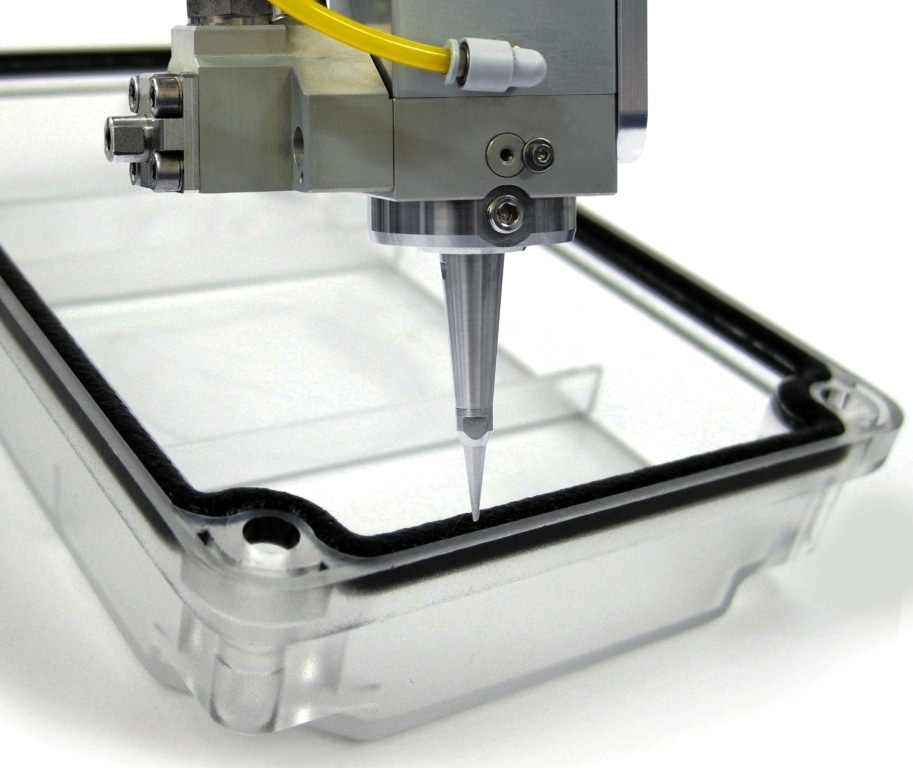

After tests and trials on a sample lid Steve Green, Techsil’s Application Engineer recommended a bespoke FIPFG (Form in Place Foam Gasket) service where a sophisticated six axis robot dispenses a single-component liquid polyurethane foam bead onto a customer’s substrate. The PU cures forming a fine, uniform, closed cell foam structure.

The FIPFG service not only allowed TRT to increase their productivity but also provided a high quality, reliable solution that passed all relevant testing and verification.

Green explains, “The project was successful in 2 ways. 1) The lids from stock are being fed to the production line already sealed and 2) the labour utilised in hand applying the gasket is deployed elsewhere. The material performed very well under stress tests and provided a reliable, aesthetically pleasing bond.”

“Short cycle times save time and money. If a manufacturer produces small volumes or has intermittent production, then subcontracting their FIPG system can be very cost effective,” says Green.

Dispensing of only one component ensures that even very small sealing gaskets can be produced accurately without any problems. However intricate the part, a perfectly engineered foam gasket can be applied; from micro-dispensing of gaskets to replace o-rings, to high volume applications of foam to doors of switch cabinets. Furthermore, the thixotropic properties of the foam ensure that very complicated tri-dimensional shapes and cross-sectional variations can be accommodated.