Nihon Superior Co. Ltd., an advanced joining material supplier, has developed a new flux-cored solder wire that greatly reduces spatter compared with conventional cored wire. The new cored-flux, (032) allows the use of a wide range of soldering iron tip temperatures with very little spatter, even with high tip temperatures.

The newly developed (032) is a general purpose, no-clean, halogen-free cored-flux. When paired with the SN100C® lead-free alloy, it provides fast wetting and excellent solder joints, not only on copper (Cu) but also nickel (Ni) substrates. SN100C (032) is a good match for continuous robotic soldering due to the fast wetting and low spattering.

(032) cored-flux is available with the company’s new SN100CVTM lead-free alloy that gains its strength from solute atoms in the tin matrix as well as SAC305 solder.

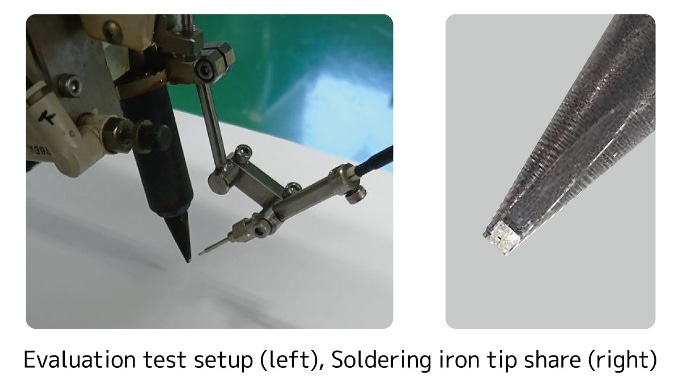

Flux Spattering Test

Test Conditions

Solder material: SN100C (032)

Supply quantity: 6.4 mm

Line diameter: 1.0 mm

Supply speed: 20 mm/second

Tip temperature: 350 °C, 380 °C, 410 °C

The test was conducted as a simulated "post soldering process" which is performed as touch-up or repair of parts after initial soldering. Evaluation was conducted with solder tip temperatures of 350° C, 380° C and 410 °C.

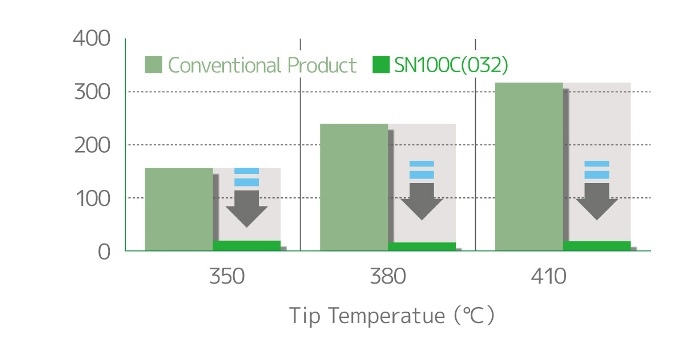

Evaluation Test Results (comparison with conventional cored wire)

“Reduced flux spattering at various temperature ranges”

Nihon Superior continues to offer solutions to the challenges facing the electronics industry, such as improvements in reliability, thermally stable joining, and lead-free die attach.