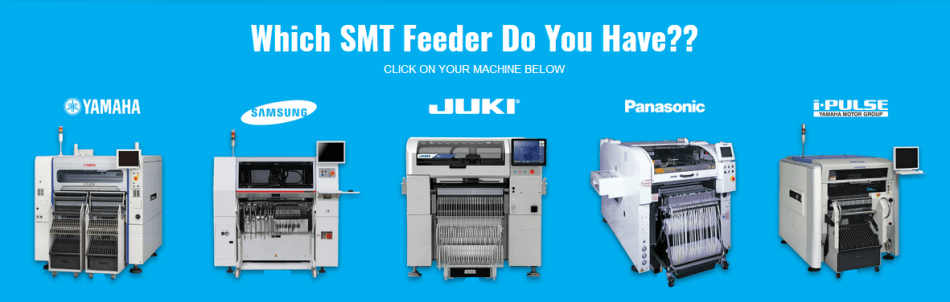

Feeder Finger, a division of Automation Technical Services, offers cut tape solutions for printed circuit board (PCB) assembly. The company offers productivity enhancing solutions for all major SMT feeders, including Juki, Samsung, Yamaha, Panasonic, Siemens, Essemtec, I-Pulse and ASM.

With the Feeder Finger solution attached to your existing OEM feeders, you reduce costs and eliminate waste by purchasing near the exact number of components required for each job without the concerns of effectively feeding strips of component tape.

ATS designed the cut tape solution to precisely fit each feeder model. The high-quality anodized aerospace machined aluminum replaces the existing tape guide. Feeder Finger allows for an unskilled operator to easily supply tape components by merely inserting the tape itself without the need for splicing or complex routing of the cover tape through the feeder. Buy what you need and save on extra costs now associated with cut tape solutions in the market.

Feeder Finger’s mission is to design innovative products that reduce costs and improve efficiency on the production floor. Feeder Finger also offers a highly efficient way to run prototypes, one-offs and NPI processes.

Feeder Finger products are designed to help customers achieve greater equipment utilization, enhance throughput with greater levels of efficiency, and enable better use of production hours.