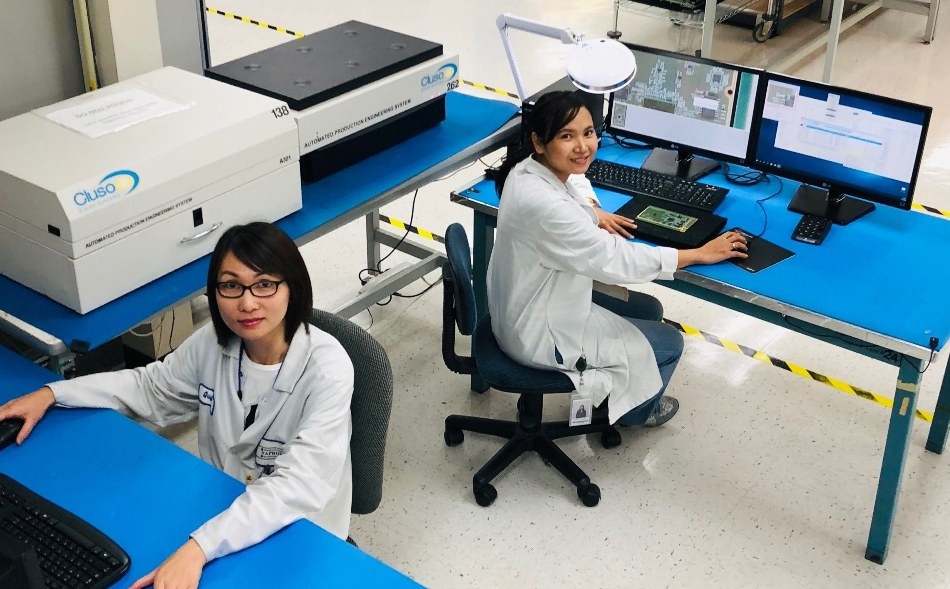

Naprotek, Inc., a provider of electronic manufacturing services, today announced that it has installed its second Automated Production Engineering (APE) system from Cluso Vision Systems. The production tool provides 100 percent inspection of first article boards without time consuming programming.

The unique system combines existing CAD, BOM and pick-and-place mount data with a high-resolution scanned image of the board to ensure that first article assemblies and documentation are accurate before entering production. Production personnel can simply step through each part to ensure the proper part, orientation and placement location are achieved.

With its new inspection system, Naprotek can inspect a typical board in less than 30 minutes, greatly reducing production downtime and eliminating downstream defects. “Naprotek continually invests in equipment and processes to increase our speed and efficiency,” commented Larry Morrissey, VP of Operations at Naprotek. “This brings added value to our customers and helps keep the entire production cycle moving forward at all times. We purchased another Cluso Vision System to help with first article validation. This system helps ensure that our SMT processes are accurate and gives us better predictability during production. It’s all about exceeding our customers’ expectations every day.”

Naprotek sets the standard for high-quality prototypes and Made-in-America production. The company specializes in mission critical products, and its processes and systems are focused on delivering award-winning quality.