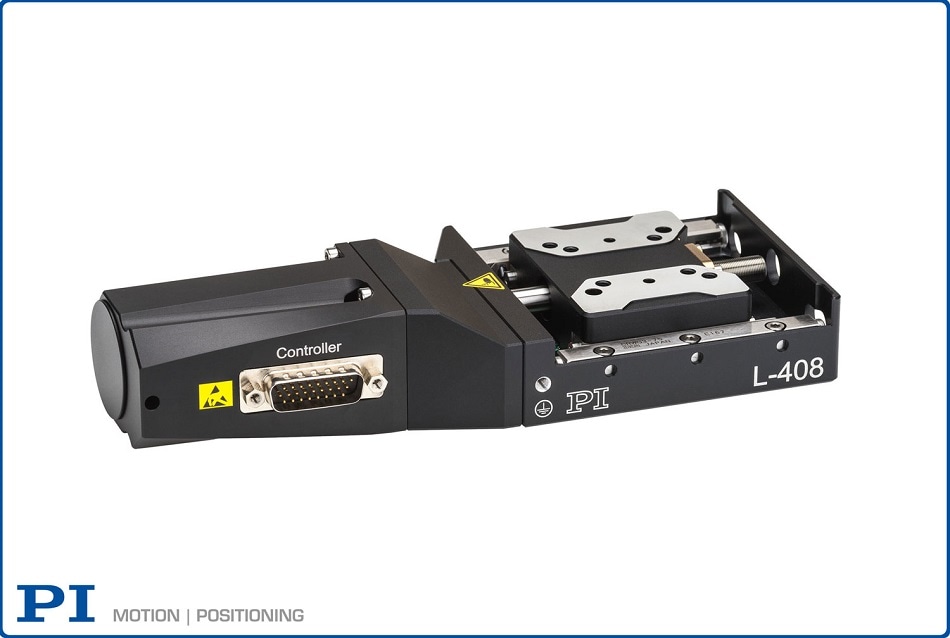

The L-408 linear stage strikes a good balance of load capacity, precision, and low cost. It has applications in research and industry including optics, bio-tech, and assembly of miniature components and photonics instrumentation.

New L-408 Linear Stage

New L-408 Linear Stage

Compact and Precise

PI’s new compact X-axis linear stage provides precise motion and reliability with anti-creep crossed roller bearings. Driven by a high resolution leadscrew with 0.5mm pitch, minimum incremental motion of 0.1 microns (100nm) is achieved over a travel range of 1 inch (25mm).

Up to 44lbs Payload (200N) and 11lb Push/Pull Force (50N)

Despite its compact dimensions, the stage can handle payloads of 44lbs (200N) and provides a push/pull force of 11lbs (50N).

What Drives It?

Stepper and servo motors are offered with direct-drive and gearbox options. The maximum velocity of the direct-drive stages is 10mm/sec. The unidirectional repeatability of all versions is 0.5 microns. High resolution, motor-mounted optical encoders provide position feedback to the motion controller for closed-loop operation.

Noncontact, optical limit switches and reference point switches with direction sensing in the middle of the travel range simplify use in automation tasks.

Specifications, Datasheet, More Information

https://www.pi-usa.us/en/products/positioning-stages-linear-rotary-motorized-precision/precision-motorized-linear-stages/l-408-compact-linear-stage-100000035/

More Miniature Linear Stages

https://www.pi-usa.us/en/products/miniature-positioning-stages-motorized-precision/

Features of the compact stages include:

- 1” (25mm) travel

- 0.1 - 0.5µm min. incremental motion

- 8 - 122nm encoder resolution

- 1 -10mm/sec max. velocity

- 40 - 50N push/pull force

- Servo & stepper motors

Standard and Custom

PI has in-house engineered solutions with over 4 decades of experience working with customers to provide products that meet application demands, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the application