PVA, a global expert in dispensing, coating and custom automation, is pleased to announce that it received a patent for its optical bonding software. The new software greatly simplifies the bonding process by providing a system that alleviates the guess-work of creating perfect bond sequences from scratch, resulting in less waste and faster time to production.

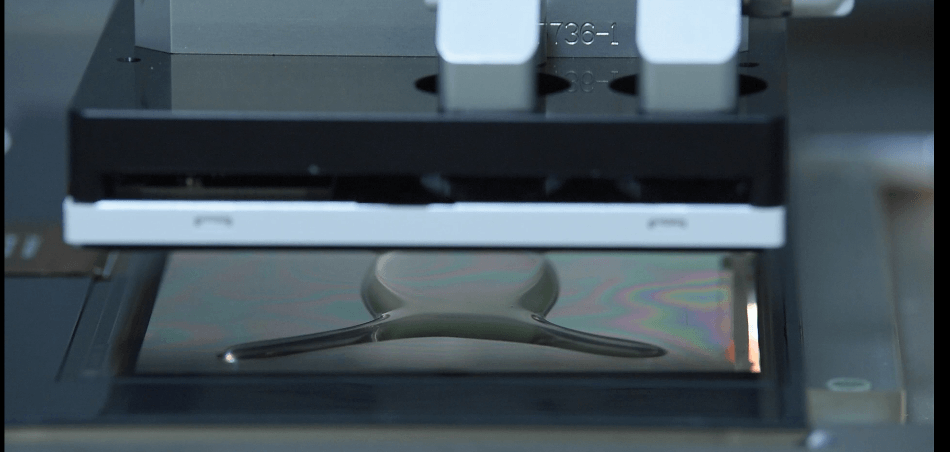

Among the numerous hurdles encountered in the optical bonding process, one of the most crucial and challenging steps is the final physical mating of the two substrates (e.g. glass to screen). With this patented feature, the user is able to have complete control over the sequence of events (speeds, distances, dwells, etc.) during this critical bonding step on an actual part in production. Using a single button and visual feedback on-screen, the user easily creates a live bond sequence while the machine is simultaneously learning and recording everything quietly in the background.

After the bond sequence has been completed, control is automatically handed back over to the machine to finish the rest of the bonding process. This “learned” bond sequence is then safely stored and can be easily recalled or modified for even more precise tuning.

Within the countless factors that go into making a perfect bond, this sequence must be highly controlled and finely tuned in order to not cause material leakage, trapped bubbles, or other defects that would result in a bad part. Leveraging this new functionality, users can now rapidly prototype and make production ready bond sequences with ease, providing speed and consistency to a once slow and complicated step in the optical bonding process.

For more information, please contact PVA at [email protected] or (518) 371-2684.