Gillette has designed a new concept to personalize the shaving experience in entirely new ways. Razor Maker™: powered by Gillette®, is a new platform leverages technology from 3D-printing powerhouse Formlabs to offer a series of customizable 3D-printed handles, matching advanced manufacturing with consumers’ desire to have completely unique and personalized products.

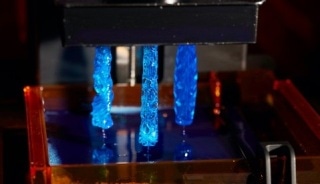

Razor Maker™ handles during the 3D-printing process

Razor Maker™ handles during the 3D-printing process

Razor Maker™ - 3D Printed Razor Handles for Personalized Experience

Razor Maker™ is an exciting concept making a limited quantity of 3D-printed razor handles available to U.S. consumers. As a brand long known for its premium quality razor blades, the addition of customizable razor handles is a natural extension for the company. Each Razor Maker™ handle is printed at Gillette’s Boston headquarters using stereolithography (SLA) printing technology from Formlabs, a Boston-area company that designs and manufactures powerful and accessible 3D-printing systems.

Consumers can create their own 3D-printed razor handle by visiting Razor Maker™ website.

- Once there, visitors choose from a range of 48 designs so intricate they can only be produced using 3D-printing technology.

- After selecting the handle, consumers personalize it further by choosing from seven color options (black, white, red, blue, green, grey and chrome) and by adding text to the design.

- Handles can accommodate either Gillette’s MACH3 or Fusion5 ProGlide razor cartridges.

“Gillette is in the business of helping men look, feel and be their best, and that means giving them access to grooming options that not only meet their shaving needs, but also match their lifestyle, look and budget,” said Pankaj Bhalla, Director, Gillette & Venus North America.

“In 2018, we introduced a range of new razor products and declared that ‘one size’ does not fit all men when it comes to razors. The Razor Maker™ pilot furthers our commitment to place power in the hands of consumers and literally have them custom-make their razors exactly the way they want them – tailored to their grooming preference, budget, look, color and style. This is one of the many ways we are fulfilling our commitment to being The Best A Man Can Get.”

Mass Customization with 3D printing is Finally Becoming a Reality

“Mass customization with 3D printing is finally becoming a reality for consumers to experience end-use printed products,” said Dávid Lakatos, Chief Product Officer of Formlabs. “Historically, 3D printing has been involved in the development or manufacturing processes for most products people interact with every day, but consumers have had little interaction with 3D printing itself. We’re thrilled to be partnering with Gillette. These new custom razor handles are the next step towards changing that dynamic and getting 3D-printed products directly into the hands of consumers.”