Feb 8 2019

A team of researchers from RIKEN and Kyushu University have created a new material based on ethylene, a compound considered to be the source of a majority of the plastic that is used nowadays. Ethylene possesses several useful properties like shape memory and self-healing. Extraordinarily, some of the materials have the potential to spontaneously self-heal even in acidic and alkali solutions or water.

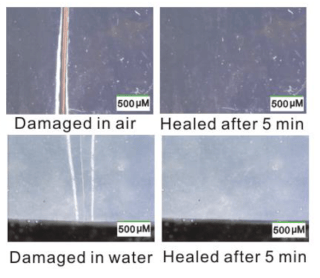

Self-healing properties Top panel: Optical microscope images of damaged (left) and repaired (right) samples of one of the materials in air at 25 °C. A film was cracked by a razor blade and then left in air for 5 minutes for healing. Bottom panel: Optical microscope images of damaged (left) and repaired (right) samples of one of the films in water at 25 °C. The film was cracked by a razor blade and then left in water for 5 minutes for healing. (Image credit: Riken)

Self-healing properties Top panel: Optical microscope images of damaged (left) and repaired (right) samples of one of the materials in air at 25 °C. A film was cracked by a razor blade and then left in air for 5 minutes for healing. Bottom panel: Optical microscope images of damaged (left) and repaired (right) samples of one of the films in water at 25 °C. The film was cracked by a razor blade and then left in water for 5 minutes for healing. (Image credit: Riken)

Over the last 10 years, materials capable of self-healing have become a popular research area, resulting in the development of a wide range of materials. Nevertheless, a good number of the self-healing materials reported till date have depended on refined designs that combine chemical mechanisms into polymer networks, such as reversible or irreversible covalent-bond formation, ionic interactions, metal-ligand interactions, or hydrogen bonding. Thus, they need some external stimulus, such as pressure or heat, that will induce them to heal, and in several cases, they do not work in alkaline solutions, acid, or water because it is just not possible for the chemical networks to survive such conditions. Hence, it is best to develop a material that can hold adequate toughness and also autonomously self-heal under different conditions.

Featuring in the Journal of the American Chemical Society, this research was carried out by researchers who used a catalyst based on scandium, a rare metal to produce polymers made up of interchanging sequences of ethylene and anisylpropylenes and shorter ethylene-ethylene segments by the copolymerization of ethylene and anisylpropylenes. This latest category of distinctively functionalized polyolefins ranged from soft viscoelastic materials to tough elastomers and rigid plastics. The soft viscoelastic materials are those capable of being elastic and yet exhibiting liquid-like properties. On the other hand, tough elastomers are those that can be stretched but they eventually return to their original shapes. The researchers discovered that the elastomer copolymers were highly elastic and hard, and also exhibited extraordinary self-healing property, as they were able to autonomously self-heal when subjected to mechanical damage in a dry environment and also in aqueous acid and alkaline solutions and water, without requiring any external stimulus or energy.

We had learned from our previous work that a scandium catalyst would be a useful way to create the copolymers of ethylene and anisylpropylenes, but we were astounded by the special properties that this class of materials exhibited. We look forward to working to find applications for these different films, which can be made easily from ethylene and other olefins.

Zhaomin Hou, Study Head, RIKEN Center for Sustainable Resource Science and RIKEN Cluster for Pioneering Research.

Scientists from the RIKEN Center for Sustainable Resource Science, RIKEN Cluster for Pioneering Research, and Kyushu University performed the research.

新しいポリマーの空気中での切断と自己修復