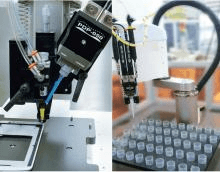

JP Kummer has recently launched three new lines of precision dispensers suitable for a wide range of industries including medical, scientific, aerospace and industrial markets in the UK and Europe. The three volumetric types of dispenser being launched are from TAEHA, NSW Corporation and Poly Dispensing Systems (PDS) and can all be used with Robots.

- TAEHA offer a range of Pro-Pump dispensers operating on the endless screw principle, achieving a smallest dispense volume of 0.5 Microlitres with repeat accuracy >99% regardless of material density or viscosity. Versions in Peek, and ceramics are available for the food, medical and pharma industries.

- NSW supply highly accurate fully automated dispensing systems with smallest dispense volume of 5 Picolitres. NSW dispensers are used mainly in semiconductor manufacturing, BGA’s, MEMs, LED potting, conformal coating, underfill and glob-top operations and custom-made versions are an option.

- PDS offer their PreciFluid® dispenser range which do not require an air supply and are suitable for Lab/R&D use together with small to medium volume production. Syringe size is 3-30cc and smallest dispense is 60 Nanolitres. PreciFluid® has a reproducibility rate of up to 99%, enabling these dispensers to improve the productivity and accuracy in dispensing applications.

Rex Sandbach, Director of JP Kummer UK, said ‘We are proud to be able to offer three types of dispensers for UK and European industry use. The unrivalled controllability of the volume of dispensing and their dosing accuracy set them apart from current dispensers used across manufacturing industry.’

With 44 years of business know-how behind them, JP Kummer was appointed as exclusive European distributors for the TAEHA and NSW Automation manufactured dispensers in 2018 to add to their existing Precifluid® line.

For more information about J P Kummer, visit https://www.jpkummer.com/.