We are excited to announce the launch of a new product, the U41, today. For the last 30 years, ACFM® technology has been used globally as the method of choice for the detection and sizing of subsea surface-breaking cracks. Recognized and approved by many certification bodies, including DNV, ABS and Lloyds, the technique has been used successfully against traditional uncomputerized and more user dependent methods, such as MPI.

Building on the excellent reputation of the previous model, the U41 brings 14 times the data resolution, performs data acquisition 10 times faster and the ability to inspect coating twice as thick as before. These benefits promise to deliver increased revenues and a quick return on investment for our customers.

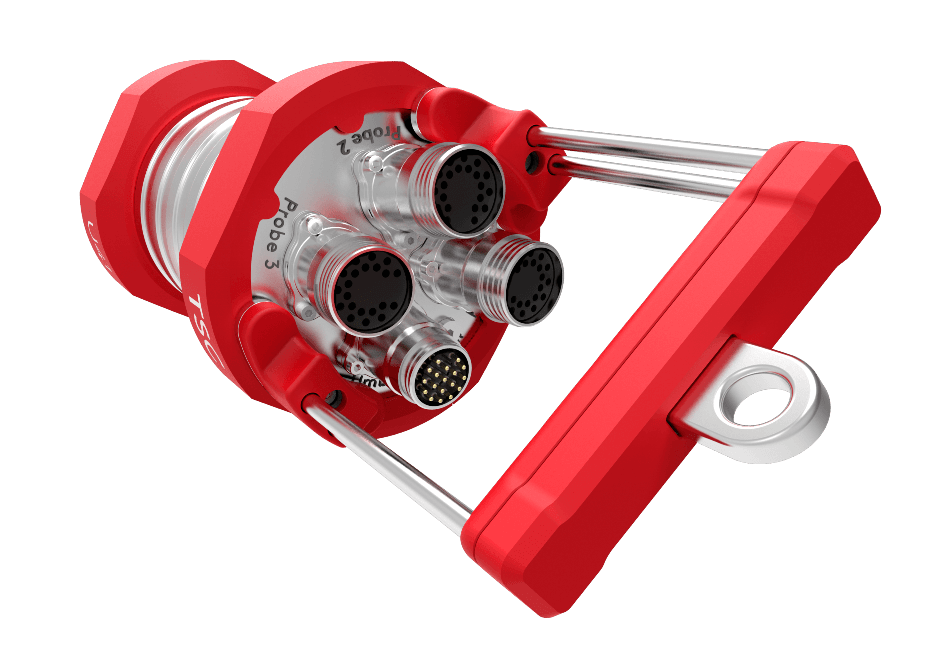

Dr. Michael Smith, Technical Director of TSC comments, “The system has been complete redesigned with new electronics, which delivers the highest resolution for ACFM data the industry has seen. New features include the ability to connect 3 probes simultaneously, which avoids frequent returns to the surface, a diver array probe which reduces the number of scans and allows for faster recognition and characterization of defects. Probe configuration files are now stored on the probe itself instead of on a remote PC, ensuring that the correct setup is used. Umbilical reel is dramatically reduced in size, weighing one third less and taking one third less space.

As today’s industry is looking to scale the use of auditable NDT methods to all their assets, faster, more reliable, easier to deploy inspections and better reporting capabilities are required. Who else but Eddyfi Technologies to redefine and modernize subsea surface crack inspection with its new TSC U41.

For an improved customer experience the TSC U41 is supported by a global network of calibration and training centres, located in Milton Keynes (UK), Québec (Canada), Houston (USA) and Dubai (UAE).

ACFM technique has been successfully deployed for the inspection of structural node welds on jackets, for caisson inspection, to assess pipeline damage, to inspect spudcans or welded plate structures, among others.