Mar 5 2019

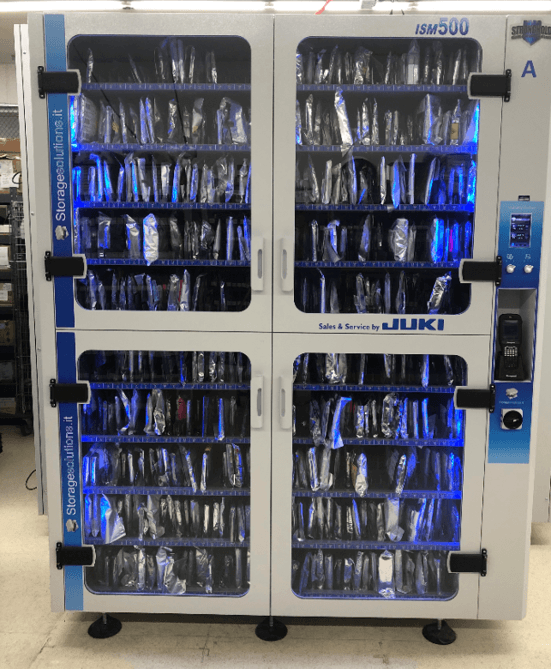

Whizz Systems, Inc. is pleased to announce that it has improved operational technology and increased production by implementing an automated warehouse system supplied by Juki Automation Systems. The automated warehouse, consisting of eight ISM 2000 Fortresses and an ISM 500 Intelligent Storage System, replaces Whizz’s warehouse consisting of shelving and racks while reducing the amount of space required.

“We are always investing in enhancing our capabilities and value that we offer to our customers,” stated Muhammad Irfan, President of Whizz Systems, Inc. “This includes equipment and training. Whizz was the first adopter of Juki the Fortress and intelligent storage systems. It is a significant investment for companies of our size, but demonstrates our commitment to excellence and we have seen great improvements.”

The Fortress is designed for optimal management of all reels, regardless of the reel diameter or thickness. Now, Whizz Systems’ automated warehouse will store all of the necessary material to run complex, high-mix, low volume, high-changeover, NPI type assemblies that the company manufactures regularly.

Whizz Systems has improved efficiency by reducing the time and labor spent trying to locate parts, as well as realizing quality improvements by always picking the correct parts. With the Fortress, there is no longer the risk of any human-error selecting the incorrect part ensuring that the correct reel is available during production runs.

Designed for the optimal management of all reels for production requirements, the Fortress offers the flexibility to support a combination of 7" reels from 8mm to 16mm in height, 13"/15" reels up to 88mm in height as well as JEDEC trays.

With the possiblity of configuring up to 640 different positions, in the ISM500 intelligent static warehouse it is possible to insert 7/13/15" reels, JEDEC trays, SMT and PTH tubes, screen-printing frames and foils, printed circuits, PTH components and more.