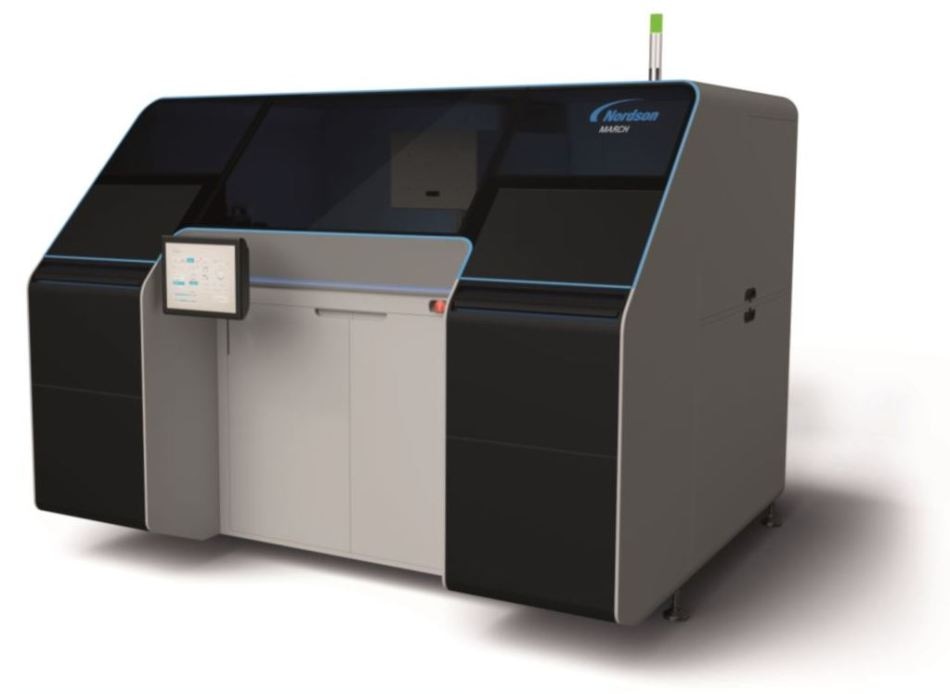

Nordson MARCH, a Nordson company, a global leader in plasma processing technology, announces the introduction of its FlexTRAK®-SHS automated plasma treatment system. The plasma system includes the 9.6-liter (585 in³) large-volume F3-S process chamber that can be configured for larger strips or can treat more strips per cycle, yielding higher throughput and increased productivity for semiconductor and electronics packaging.

The FlexTRAK-SHS system's advanced automation enables high-throughput processing of lead frames, high-density substrates, and other strip-type electronic components. The system handles simultaneous strip buffering and plasma processing for higher chamber utilization. Advanced process controls, interchangeable electrode configurations, and plasma modes give ultimate application flexibility.

The plasma chamber of the FlexTRAK-SHS employs the same architecture and technology as the smaller FlexTRAK platforms for a seamless transition as production demands more capacity. It is capable of processes such as surface cleaning, oxidation removal, organic contamination removal, and surface activation. FlexTRAK-SHS is CE marked and meets SEMI S2/S8 (EH&S/Ergonomics) standards.

Key applications for plasma cleaning include:

- Pre-wire bond plasma treatment on semiconductor package substrates and lead frames

- Pre-underfill plasma treatment on flip-chip packages

- Pre-mold plasma treatment on semiconductor package substrates and lead frames

- Plasma treatment of semiconductor package substrates and lead frames for improved adhesion

- Removal/reduction of oxidation on lead frames.

"FlexTRAK-SHS is the latest in Nordson MARCH's TRAK® series of automated plasma systems and is designed to fulfill our customers' requirements to develop new processes to improve product performance and increase productivity while reducing costs," said Daniel Chir, product line manager, Nordson MARCH. "Built upon MARCH's patented plasma technology, the FlexTRAK-SHS is our most advanced automated plasma system, increasing productivity to new levels while providing the same unparalleled treatment uniformity and process consistency as our other TRAK series plasma systems."