Apr 1 2019

Quartz glass is the favored material for applications that necessitate long-term use because of its high mechanical and chemical stability and outstanding optical properties. The engineer Prof. Dr. Bastian E. Rapp from the Department of Microsystems Engineering (IMTEK) at the University of Freiburg and his team have formulated the Glassomer process, a technique that allows researchers to form glass like plastic. In the scientific journal Nature Communication, they recently publicized a new application: They are currently able to create three-dimensional hollow structures in quartz glass.

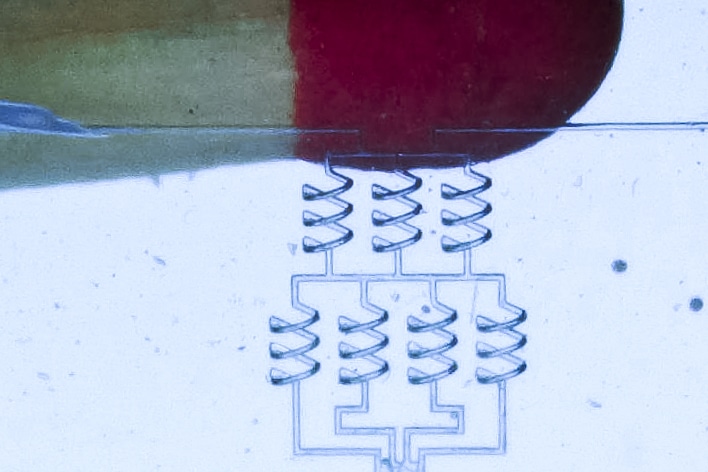

Three-dimensional hollow structures in quartz glass. (Photo credit: AG Rapp)

Three-dimensional hollow structures in quartz glass. (Photo credit: AG Rapp)

Glass is chemically extremely resistant, which is why cavities such as microfluidic channels or optical waveguides are hard to produce in it, particularly if they have to be three-dimensional. The Glassomer process formulated by Rapp and his team streamlined this process. Glassomer is a mixture in which high-purity silicon oxide is incorporated in fine powder form to a liquid plastic. As long as this mixture is liquid, it can be processed in the same way as a plastic. When exposed to light, it toughens so that it can, for instance, be milled or drilled. During the last heat treatment step in the process, the plastic is decomposed leaving behind a dense glass component. So far, channel structures could not be produced because the scientists had to eliminate the liquid material from the cavities which is not feasible for long channels.

The Freiburg researchers are, thus, following a different tactic by first producing the desired cavity as a polymeric component in the 3D printer: A later channel is printed as a polymer thread and later encapsulated with Glassomer. The final printed product is then heated to 1,300 °C so that the plastic as well as the polymer thread is decomposed. The outcome is a channel surrounded by real glass.