May 9 2019

Arindam Banerjee, an associate professor of mechanical engineering and mechanics at Lehigh University, explores the dynamics of materials in challenging environments. He and his team have developed more than a few devices to effectively examine the dynamics of fluids and other materials under the impact of high acceleration and centrifugal force.

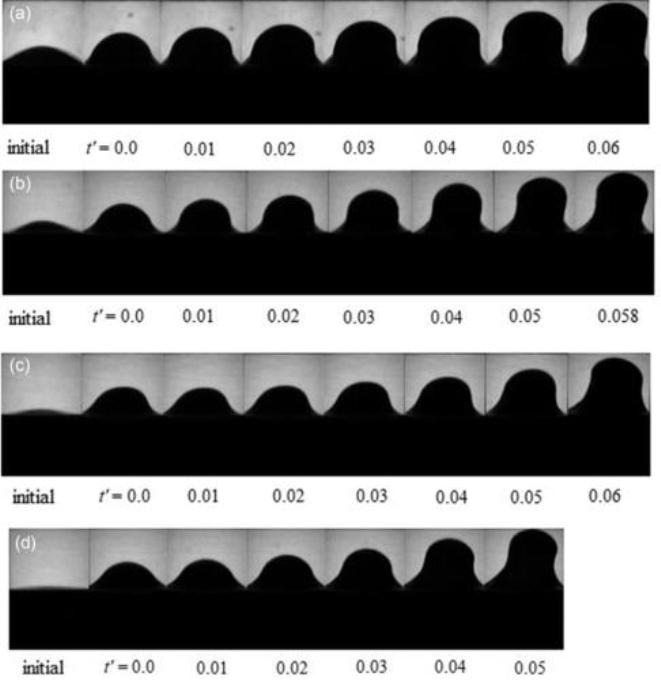

These are experimental images for 3D initial perturbation. (Image credit: Arindam Banerjee)

These are experimental images for 3D initial perturbation. (Image credit: Arindam Banerjee)

One area of interest is Rayleigh-Taylor instability, which happens between materials of varying densities when the density and pressure gradients are in opposite directions forming an unstable stratification.

"In the presence of gravity? or any accelerating field? the two materials penetrate one another like 'fingers,'" says Banerjee.

According to Banerjee, the understanding of the instability is mostly limited to fluids (gases or liquids). Not a lot is known about the development of the uncertainty in accelerated solids. The short time scales and large measurement reservations of accelerated solids make exploring this sort of material very difficult.

Banerjee and his team have been successful in describing the interface between an elastic-plastic material and a light material under acceleration. They learned that the beginning of the instability? or "instability threshold"? was connected to the size of the amplitude (perturbation) and wavelength (distance between crests of a wave) applied. Their results revealed that for both 2D dimensional and 3D perturbations (or motions) a decrease in original amplitude and wavelength created a more steady interface, thereby raising the acceleration necessary for instability.

These results can be found in a paper published recently in Physical Review E called "Rayleigh-Taylor-instability experiments with elastic-plastic materials." Besides Banerjee, co-authors include Rinosh Polavarapu (a current Ph.D. student) and Pamela Roach (a former M.S. student) in Banerjee's group.

There has been an ongoing debate in the scientific community about whether instability growth is a function of the initial conditions or a more local catastrophic process. Our experiments confirm the former conclusion: that interface growth is strongly dependent on the choice of initial conditions, such as amplitude and wavelength.

Arindam Banerjee, Associate Professor of Mechanical Engineering and Mechanics, Lehigh University

During experiments, Hellman's Real Mayonnaise was drizzled into a Plexiglass container. Diverse wave-like perturbations developed on the mayonnaise and the sample was then accelerated on a rotating wheel experiment. The material’s growth was tracked using a high-speed camera (500 fps). An image processing algorithm, written in Matlab, was then applied to compute different parameters related to the instability. For the effect of amplitude, the preliminary conditions were ranged from w/60 to w/10 while the wavelength was differed from w/4 to w to explore the effect of wavelength ("w" signifies the size of the width of the container). Experimental growth rates for several wavelength and amplitude combinations were then compared to current analytical models for such flows.

This work allows scientists to visualize both the elastic-plastic and instability evolution of the material while offering a beneficial database for development, validation, and corroboration of models of such flows, says Banerjee.

He adds that the new understanding of the "instability threshold" of elastic-plastic material under acceleration could be beneficial in helping to crack challenges in astrophysics, geophysics, industrial processes such as explosive welding, and high-energy density physics problems connected to inertial confinement fusion.

Understanding the hydrodynamics of inertial confinement

Banerjee is involved in one of the most promising approaches to realize nuclear fusion known as inertial confinement. In the U.S., the two prominent labs for this research are the National Ignition Facility at the Lawrence Livermore National Laboratory in Livermore, California—the leading operational inertial confinement fusion experiment in the U.S.—and the Los Alamos National Laboratory in New Mexico. Banerjee is associated with both. He and his team are attempting to comprehend the core hydrodynamics of the fusion reaction, as well as the physics.

In inertial confinement experiments, the gas (hydrogen isotopes, like in magnetic fusion) is frozen within pea-sized metal pellets. The pellets are positioned in a chamber and then bombarded with high-powered lasers that compress the gas and heat it to a few million Kelvin—about 400 million °F—forming the settings for fusion.

The huge transfer of heat, which takes place in nanoseconds, melts the metal. Under enormous compression, the gas inside wants to force itself out, causing an undesirable outcome: The capsule bursts before fusion can be realized. One way to make sense of this dynamic, explains Banerjee, is to visualize a balloon being squeezed.

As the balloon compresses, the air inside pushes against the material confining it, trying to move out. At some point, the balloon will burst under pressure. The same thing happens in a fusion capsule. The mixing of the gas and molten metal causes an explosion.

Arindam Banerjee, Associate Professor of Mechanical Engineering and Mechanics, Lehigh University

To stop the mixing, adds Banerjee, one has to understand how the molten metal and heated gas combine in the first place.

To discover this, his team runs experiments that imitate the settings of inertial confinement, isolating the physics by eliminating the temperature gradient and the nuclear reactions.

Banerjee and his team have spent over four years constructing a device, particularly for these experiments. Lodged in the first floor of Lehigh's Packard Laboratory, the experiment is the only one of its kind in the world, as it can explore two-fluid mixing at conditions applicable to those in inertial confinement fusion. High-tech equipment is also available for diagnosing the flow. The projects are sponsored by the Department of Energy, Los Alamos National Laboratory and the National Science Foundation.

One of the means that scientists like Banerjee mimic the molten metal is by using mayonnaise. At a high temperature, the material properties and dynamics of the metal are a lot like those of mayonnaise at low temperature, he says.

The device made by the team re-creates the unbelievable speed at which the gas and molten metal are blending. They collect data from the experiments they conduct and then feed it into a model being designed at Los Alamos National Lab.

They have taken a very complicated problem and isolated it into six or seven smaller problems. There are materials scientists working on certain aspects of the problem; there are researchers like me who are focused on the fluid mechanics—all feeding into different models that will be combined in the future.

Arindam Banerjee, Associate Professor of Mechanical Engineering and Mechanics, Lehigh University