Jun 25 2019

Scientists will have to first comprehend how soft materials behave during swiftly changing deformation before designing the next generation of soft materials. In a new research, scientists challenged earlier assumptions concerning polymer behavior with newly formulated laboratory methods that measure polymer flow at the molecular level.

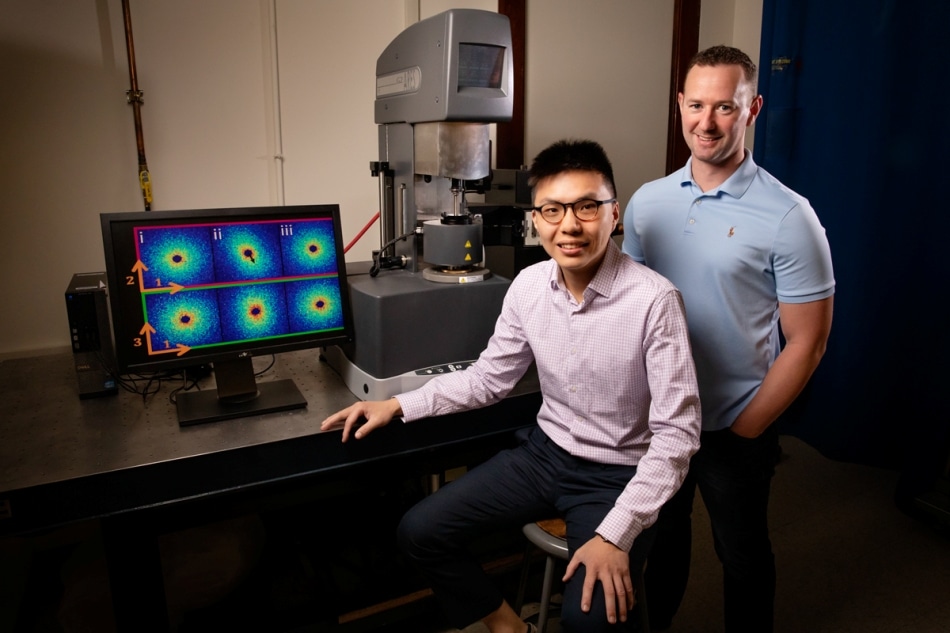

Chemical and biomolecular engineering researchers Johnny Ching-Wei Lee, left, professor Simon Rogers and collaborators are challenging previous assumptions regarding polymer behavior with their newly developed laboratory techniques that measure polymer flow at the molecular level. (Photo by L. Brian Stauffer)

Chemical and biomolecular engineering researchers Johnny Ching-Wei Lee, left, professor Simon Rogers and collaborators are challenging previous assumptions regarding polymer behavior with their newly developed laboratory techniques that measure polymer flow at the molecular level. (Photo by L. Brian Stauffer)

This method may pave the way towards the design of new industrial, biomedical, and environmental applications – from polymers that help in blood clotting to materials that more efficiently can extract oil and gas from wells.

The findings have been reported in the journal Physical Review Letters.

Gaining an insight into the mechanics of how materials molecularly react to varying flows is crucial to creating superior quality materials, the scientists said, and establishing a framework for inferring and describing these properties has evaded researchers for several years.

“When polymeric materials – synthetic or biologic – are deformed, they react at both macroscopic and molecular scales,” said Simon Rogers, a University of Illinois chemical and biomolecular engineering professor and lead author of the new study. “The relationship between the two scales of response is complex and has been, until now, difficult to describe.”

Earlier studies have tried to define the relationship between the microscopic and macroscopic actions of polymer deformation mathematically, the scientists said, but have been incapable of connecting the physics to any well-established microstructural observations.

In our study, we wanted to measure both the structural and mechanical properties of polymers during deformation, directly shedding light on the origin of unique mechanical properties. We thought perhaps it was best to try and use direct observations to explain the complex physics.

Johnny Ching-Wei Lee, Graduate Student and Study Co-Author, University of Illinois

In the lab, the team concurrently measured multiscale deformations by bringing together traditional tools for computing stress and deformation at the macroscopic level with a method known as neutron scattering to view the structure at the molecular scale.

The team learned something surprising.

“With simultaneous neutron scattering and flow measurements, we are able to directly correlate structure and mechanical properties with a time resolution on the order of milliseconds,” said study co-author Katie Weigandt, a researcher from the National Institute of Standards and Technology Center for Neutron Science. “This approach has led to fundamental understanding in a wide range of nanostructured complex fluids, and in this work, validates new approaches to making polymer flow measurements. ”

“Previous research had assumed that the amount of applied deformation at the macroscale is what soft materials experience at the microscale,” Lee said. “But the neutron-scattering data from our study clearly shows that it is the deformation that can be recovered that matters because it dictates the whole response, in terms of macroscopic flow – something that was previously unknown.”

The scientists said this development will help correct numerous poorly understood occurrences in polymers research, for example, why do polymers expand during 3D printing processes.

We have come up with what we call a structure-property-processing relationship. This subtle, yet fundamentally different way of thinking about the polymer behavior summarizes what we see as a simple and beautiful relationship that we expect to be quite impactful.

Simon Rogers, Study Lead Author and Chemical and Biomolecular Engineering Professor, University of Illinois

The research offers crucial insights to the long-standing challenge in soft condensed matter, and the team said the defined structure-property-processing relationships could give a new design standard for soft materials.

Katie M. Weigandt and Elizabeth G. Kelley of the Center for Neutron Research at the National Institute of Standards and Technology also contributed to the research.

The research was supported by the National Science Foundation.