Jun 28 2019

Scientists from the Chalmers University of Technology, Sweden, have achieved 3D printing with a wood-based ink that can mimic the special “ultrastructure” of wood.

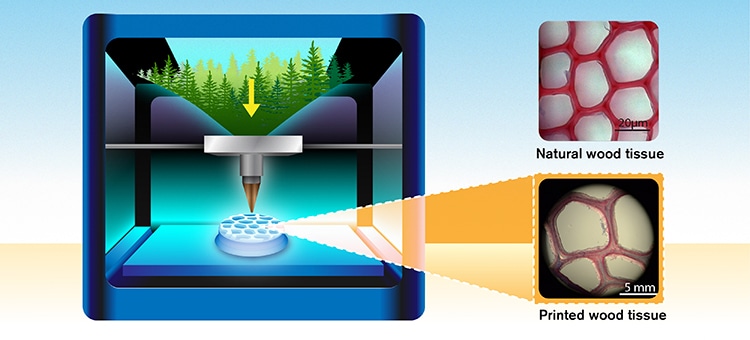

Mimicking the natural cellular architecture of wood. The printed version is at a larger scale for ease of handling and display, but the researchers are able to print at any scale. (Image credit: Yen Strandqvist/Chalmers University of Technology)

Mimicking the natural cellular architecture of wood. The printed version is at a larger scale for ease of handling and display, but the researchers are able to print at any scale. (Image credit: Yen Strandqvist/Chalmers University of Technology)

Their research may revolutionize the production of green products. The researchers, by mimicking the natural cellular architecture of wood, were able to produce green products derived from trees, with exceptional properties—all from packaging, clothes, and furniture to personal care and healthcare products.

The growth of wood is controlled by its genetic code, from which it obtains its unique properties in terms of toughness, porosity, and torsional strength. Wood, however, has restrictions with regard to processing. Different from plastics and metals, it cannot be thawed and simply reshaped and rather ought to be sawn, curved, or planed. In the processes that involve conversion, for manufacturing products such as card, paper, and textiles, the underlying ultrastructure or architecture of the wood cells are destroyed. However, the newly introduced technology allows wood to be, indeed, grown into the exact desired shape of the final product, through the medium of 3D printing.

By converting wood pulp into a nanocellulose gel, Chalmers researchers had a previously succeeded in developing a kind of 3D-printed ink. At present, they have shown a major development—successfully interpreting and digitizing genetic code of wood, so that it can direct a 3D printer.

This means that at present, the arrangement of the cellulose nanofibrils can be accurately controlled during the process of printing to actually duplicate the wood’s desirable ultrastructure. The ability to achieve the shape and orientation means they can obtain those useful characteristics of natural wood.

This is a breakthrough in manufacturing technology. It allows us to move beyond the limits of nature, to create new sustainable, green products. It means that those products which today are already forest-based can now be 3D printed, in a much shorter time. And the metals and plastics currently used in 3D printing can be replaced with a renewable, sustainable alternative.

Paul Gatenholm, Professor, Wallenberg Wood Science Centter, Chalmers University of Technology

Gatenholm has conducted this study.

A further development on earlier research is the addition of hemicellulose—a natural component of plant cells—to the nanocellulose gel. The hemicellulose serves as a glue and offers the cellulose enough strength to be useful, in a way that is similar to the natural process of lignification, by which cell walls are constructed.

The novel technology could pave the way for a whole new area of possibilities. At present, wood-based products could be created and “grown” to order—at a highly reduced timescale when compared to natural wood.

Paul Gatenholm’s team has previously created a prototype for a novel packaging concept. They printed out honeycomb structures, with chambers in between the printed walls, and were later able to enclose solid particles inside those chambers. Cellulose is known to have excellent oxygen barrier properties, which means that this could be a potential method to create airtight packaging for pharmaceuticals or foodstuffs.

Manufacturing products in this way could lead to huge savings in terms of resources and harmful emissions. Imagine, for example, if we could start printing packaging locally. It would mean an alternative to today’s industries, with heavy reliance on plastics and CO2-generating transport. Packaging could be designed and manufactured to order without any waste.

Paul Gatenholm, Professor, Wallenberg Wood Science Center, Chalmers University of Technology

The researchers have also created prototypes for clothing and healthcare products. Space is another area where Paul Gatenholm perceives a great potential for the technology and believes that it provides the ideal first test bed to improve the technology further.

The source material of plants is fantastically renewable, so the raw materials can be produced on site during longer space travel, or on the moon or on Mars. If you are growing food, there will probably be access to both cellulose and hemicellulose.

Paul Gatenholm, Professor, Wallenberg Wood Science Center, Chalmers University of Technology

The scientists have already successfully explained their technology at a workshop at the European Space Agency (ESA). They have been working with Florida Tech and NASA on another project, which includes tests of materials in microgravity.

According to Gatenholm, “Traveling in space has always acted as a catalyst for material development on earth.”