Market leader in temperature controlled microscopy, Linkam Scientific Instruments, has launched the latest version of the tensile stage, the new Modular Force Stage (MFS). Designed to characterise the mechanical properties of samples, the system is a new and improved version of the popular TST350 tensile stage with increased sensitivity, resolution and a modular design.

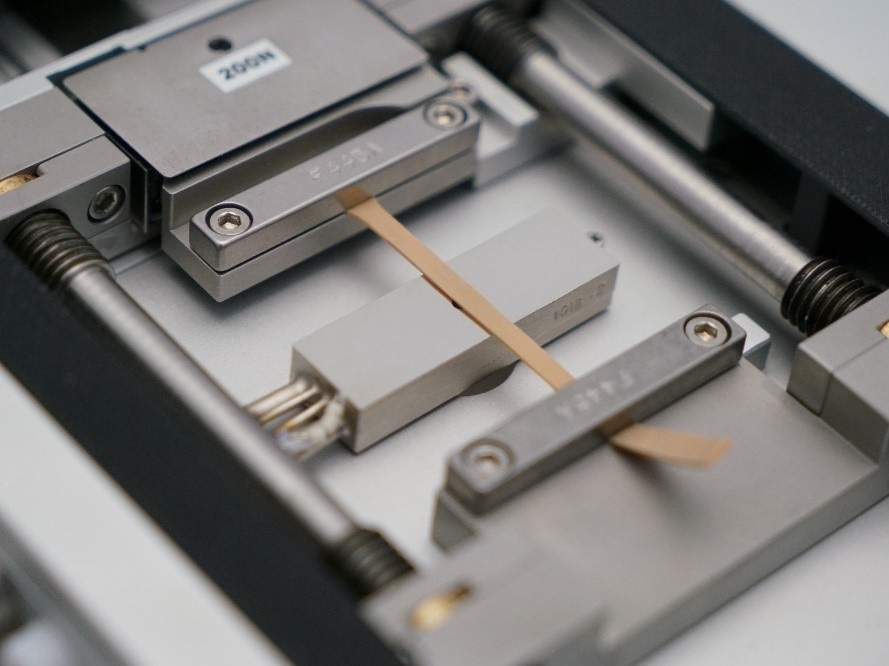

The new MFS is a compact system with a temperature, gas and, optional humidity-controlled sample environment. It can be mounted on a microscope which can be used to directly image changes in the microstructure of a material while it is undergoing tensile (in-situ) testing. Correlating this optical information with the physical characteristics measured by the MFS stage provides invaluable information related to the overall performance of a material in a given environment.

The modular design allows users to have an additional level of control over their experiments with the ability to change grips, heater types and force beams. It offers a flexible upgrade and customisation path and has been designed to accommodate a wide range of different samples and applications, from carbon fibre and graphene in engineering, to new materials for surgical implants and much more.

The MFS adds encoded distance measurement, improved force resolution, full compression capability as well a multi-point bending. It can be used with reflected or transmitted illumination as well as other techniques such as X-ray, Raman and FTIR. Its sample chamber can be gas purged via the built-in gas ports.

To address the needs of life science applications, Linkam has developed a temperature controlled base suitable for a petri dish. Now tissue samples can be tested in an aqueous solution, so they are maintained in a close to natural environment. There are a range of heater options available, from -196°C up to 350°C, allowing the structural dynamics of sample materials to be observed and imaged while under defined temperature and tensile, compressive, or bending profiles. The high resolution encoding provides accurate distance measurement, which is critical for precise strain measurement applications.

The new tensile stage can be combined with the Linkam Humidity generator, RH95, to further expand the range of tests possible. There is also an option for electrical connections. These have been used to test some of the new photovoltaic (PV) materials and other sensors that are now being developed for wearable technology or fashion tech applications.

Linkam will be adding additional options for the MFS in the future, to address the specific needs of its customers.

Standard tensile and compressive testing systems tend to be large, making it difficult to test small samples. They also tend to work in ambient conditions and while ideal for testing bulk materials it is not easy to understand the microstructure of a material. The new MFS represents a real step change in the ability to understand the micro and thermo mechanical properties of materials. We have been developing this unique upgrade in close partnership with our customers to meet the challenges they face with the materials being employed to meet ever higher engineering demands. The new MFS is designed to meet the highest standards in tensile testing to provide reliable and accurate results relative to temperature.

Duncan Stacey, Sales and Marketing Director, Linkam

Visit Linkam at www.linkam.co.uk and learn about the broad range of applications in the field of temperature-controlled microscopy.