ELIX Polymers has added two new grades to the Ultimaker Marketplace for 3D printing equipment FDM applications.

The move was made together with three partner companies producing filament from ELIX ABS: 3R3D, based in Spain; Filoalfa brand owner Ciceri de Mondel (Italy); and Print-me (Poland). The companies in the partnership cooperated within the Ultimaker Material Alliance Program.

New ABS Grades - ELIX 3D-FC and ELIX ABS 3D-HI

The two new ABS grades are ELIX 3D-FC and ELIX ABS 3D-HI.

ELIX 3D-FC

- ELIX 3D-FC is certified for medical and food contact applications, complying with the ISO 10993-1 and USP Class VI standards determining biocompatibility.

- Certification covers the whole material recipe, including color pigments (the material is available in different colors).

ELIX 3D-HI

- The second grade, ELIX 3D-HI, is a high-impact ABS grade with lower density than other ABS grades and offering very high impact resistance, even at very low temperatures.

- Impact performance is comparable with ABS/PC, which has a higher density, making the new grade particularly suitable for automotive applications where weight-saving is an issue.

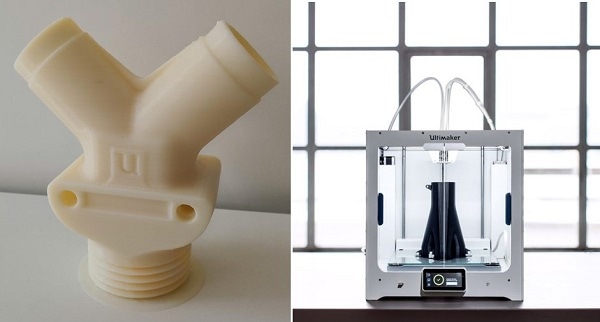

- Both new ELIX grades offer superior layer adhesion and 3D printing results.

- Possible applications include functional prints of prototype parts (assembly tests in automotive, for example), industrial/medical tooling (jigs and fixtures), and short series of personalized parts.

“We are very excited to make these new ABS materials available via the Ultimaker Material Alliance Program,” said Luca Chiochia, ELIX Business development Manager, “particularly as some of our traditional injection moulding customers are now starting to adopt Ultimaker 3D printers.”

At Ultimaker, Bart van As, Product Manager Materials, added: “I am very happy that these specialty materials are added to the expanding range of materials available in the Ultimaker Marketplace. Together with our partners, we are opening up new applications for 3D printing with our printers.”

Ultimaker Alliance Program

“We are really proud to cooperate with ELIX and be part of the Ultimaker Alliance Program,” said Antonio Berera, research and development manager at Ciceri de Mondel. “Our company has innovation and research to develop better 3D printing materials in its DNA. We believe the results we have achieved together are very interesting in the panorama of ABS for 3D printing.”

At Print-me, Mateusz Kasprowiak said: “We are able to make such good quality filaments thanks to the excellent raw materials from ELIX Polymers optimized for 3D printing. We are proud of having the opportunity to participate in the Ultimaker Material Alliance Program, and that our material works with Ultimaker hardware.”

“Our customers demand more and more warranty of performance of our filaments in 3D printers, and require accurate and clear print profiles,” said Josu Aseguinolaza at 3R3D. “Our company is participating with its wide range of eco-sustainable and high-performance filaments in open programs involving several brands of 3D FDM printers, with ELIX Polymers materials, and with other compounders.”

During the Hannover Messe in April, Ultimaker – the global leader in desktop 3D printing – announced that its Ultimaker Material Alliance Program had already influenced over 80 companies worldwide to develop material print profiles for FFF 3D printing. The program was launched a year earlier to meet the growing demand for industrial-grade engineering 3D printing materials.

Today, many leading material manufacturers and filament producers use Ultimaker’s Print Profile Assistant to more rapidly bring a wide variety of high-performance FFF 3D printing materials to the professional market. These material print profiles become available for download in the Marketplace in Ultimaker Cloud.