Reducing the specific energy requirements from fine grinding by even a small amount is critical to cost savings and boosting the returns from mineral processing.

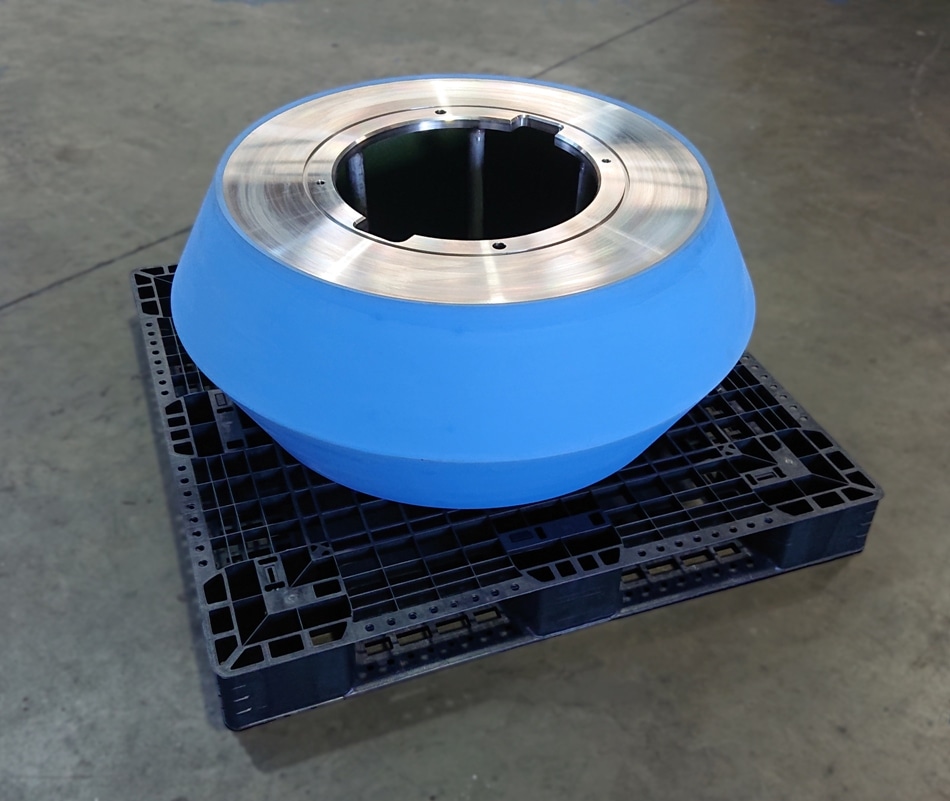

Conical on Pallet

Conical on Pallet

Glencore Technology has developed, tested and now commercialised conical spacers for their IsaMillTM fine grinding technology that have achieved extremely significant reductions in energy draw.

Tests in an IsaMill processing pyrite concentrate for gold recovery showed they reduced the specific energy requirement by 12.7% to 21.5% depending on the P80 requirements. The greater the fine grinding duty the greater the savings recorded.

At the same time, and just as important, the new conical spacers have no adverse effect on the particle size distribution. They simply reduce the specific energy required to produce a given product size.

Technology manager, Virginia Lawson, said the IsaMill had already been shown to grind metalliferous concentrates to a smaller size and to be significantly more energy and metallurgically efficient than conventional ball mills and tower mills.

But it was imperative for the company to explore ways of finding further efficiency gains to contribute to the deliverables of an IsaMillTM. The testwork program progressed from the laboratory to pilot scale and then to a production scale M1000 IsaMill before being installed permanently on that mill.

The specific energy reduction – and potential reduction in regrinding power bill for the client – improved with the fineness of the regrind product: grinding to a P80 of 22um produced a 12.7% saving, while fine grinding to 15um saved 21.5%.

Lawson says the results are incredibly significant for users of an IsaMillTM and for those considering investing in a new fine grinding asset.

“These specific energy savings offer the potential for a significant reduction in the operating costs of fine grinding. The IsaMillTM is already delivering industry leading energy efficiency and availability. But these savings make it incredibly compelling to retrofit existing IsaMills and to specify an IsaMill in any redesigned or new flowsheet.”

Lawson said the spacers were best suited to sites with relatively fine grind size targets and high specific energy consumptions. A paper detailing these gains, “Improving IsaMill™ Energy Efficiency through Shaft Spacer Design”, was published in Minerals Engineering Journal.

The IsaMillTM turns 25 in 2019, with the first IsaMills ever deployed still in operation in McArthur River and Mt Isa.