Jul 23 2019

Electrical engineers at the University of Illinois (U. of I.) have added beta-gallium oxide—the field’s hottest material—to their arsenal, thus overcoming another barrier in the fabrication of high-power semiconductors.

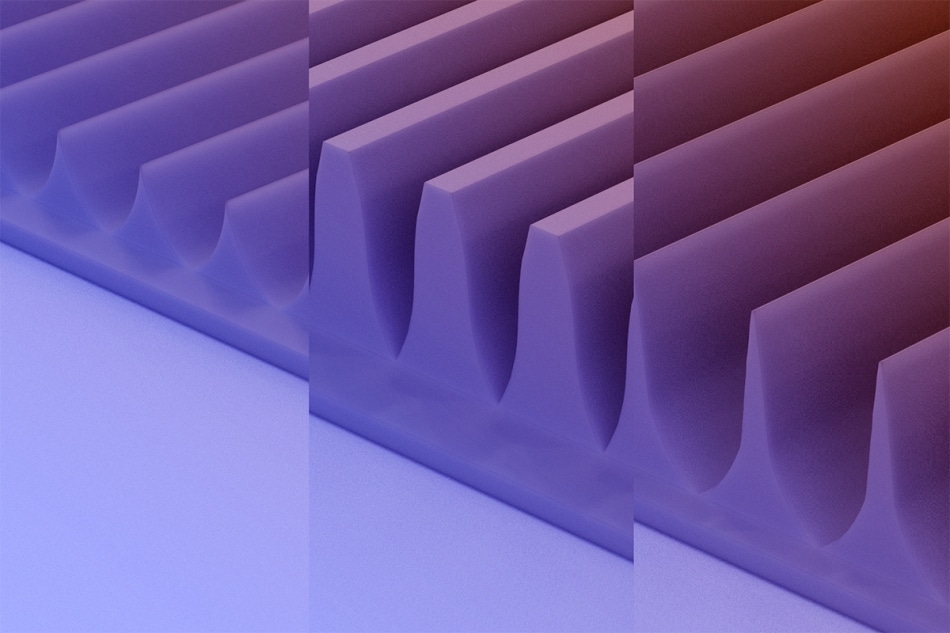

An artist rendering of the MacEtch-produced fin array structures in a beta-gallium oxide semiconductor substrate from professor Xiuling Li’s latest project. (Image credit: ACS Nano)

An artist rendering of the MacEtch-produced fin array structures in a beta-gallium oxide semiconductor substrate from professor Xiuling Li’s latest project. (Image credit: ACS Nano)

When compared to current leading semiconductor materials, such as silicon and gallium nitride, beta-gallium oxide has the potential to change power more quickly and efficiently. Moreover, the compound is also readily available, stated the researchers. The results of the study have been reported in the journal, ACS Nano.

Although flat transistors have become roughly as small as is physically viable, scientists have resolved this issue by going vertical. Engineers at the University of Illinois leveraged a method known as metal-assisted chemical etching, or MacEtch, in which a chemical solution was used to etch semiconductor into three-dimensional (3D) fin structures.

These fins boost the surface area on a chip, enabling more current or transistors. They can therefore handle more amounts of power and, at the same time, make sure that the footprint of the chip remains the same size.

The MacEtch method—developed at the U. of I.—is better than conventional “dry” etching method because it does not cause much damage to fragile semiconductor surfaces, like beta-gallium oxide, stated the research team.

Gallium oxide has a wider energy gap in which electrons can move freely. This energy gap needs to be large for electronics with higher voltages and even low-voltage ones with fast switching frequencies, so we are very interested in this type of material for use in modern devices. However, it has a more complex crystal structure than pure silicon, making it difficult to control during the etching process.

Xiuling Li, Study Lead Author and Professor, Electrical and Computer Engineering, University of Illinois

According to Li, the semiconductor industry can considerably benefit by applying MacEtch to gallium oxide crystals, but the advancement certainly involves challenges.

“Right now, the etching process is very slow,” she stated. “Because of the slow rate and the complex crystal structure of the material, the 3D fins produced are not perfectly vertical, and vertical fins are ideal for efficient use of power.”

In the latest analysis, trapezoidal, triangular¸ and tapered fins were produced by the beta-gallium oxide substrate based on the orientation of metal catalyst layout in relation to the crystals. While these shapes cannot be said to be perfect, the scientists were amazed to discover that they still do a better job at conducting current when compared to the flat and unetched surfaces of the beta-gallium oxide.

We are not sure why this is the case, but we are starting to get some clues by performing atomic-level characterizations of the material. The bottom line is that we have shown it is possible to use the MacEtch process to fabricate beta-gallium oxide, a potentially low-cost alternative to gallium nitride, with good interface quality.

Xiuling Li, Study Lead Author and Professor, Electrical and Computer Engineering, University of Illinois

According to Li, more studies will need to deal with the slow etch rate, facilitate high-performance beta-gallium oxide devices, and attempt to resolve the issue of low thermal conductivity.

“Increasing the etch rate should improve the process’s ability to form more vertical fins,” she added. “This is because the process will happen so quickly that it will not have time to react to all of the differences in crystal orientations.”

She further stated that the low thermal conductivity issue is a more profound problem. “High-power electronics produce a lot of heat, and device researchers are actively seeking thermal engineering solutions. While this is a wide-open aspect in the semiconductor field right now, 3D structures like what we have demonstrated could help guide the heat out better in some device types,” she added.

Li is affiliated with the Nick Holonyak Jr. Micro and Nanotechnology Laboratory, the Frederick Seitz Materials Research Laboratory, and the Beckman Institute for Advanced Science and Technology at the U. of I.

Other researchers who participated in this study were Hsien-Chih Huang, Munho Kim, Xun Zhan, Jian-Min Zuo and Jeong Dong Kim of the U. of I; Kelson Chabak of the Air Force Research Laboratory, Sensors Directorate; and Alexander Kvit, Dong Liu, and Zhenqiang Ma of the University of Wisconsin, Madison. At present, Munho Kim is with Nanyang Technology University, Singapore.

The study was supported by the National Science Foundation and the U.S. Department of Energy.