Jul 24 2019

Diamonds are not merely a girl’s best friend—they are also important components for hard-wearing industrial parts, such as the drill bits used to reach oil and gas deposits underground. But an economical technique to find other appropriate materials to perform the task is on the way.

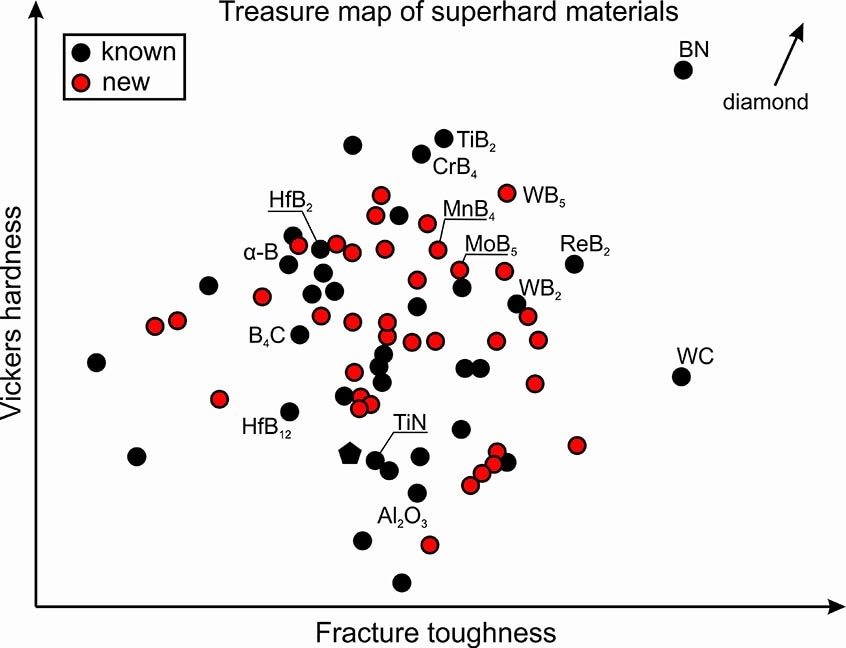

Ashby plot showing materials with the best combination of high hardness and fracture toughness. (Image credit: Alexander Kvashnin, Skoltech)

Ashby plot showing materials with the best combination of high hardness and fracture toughness. (Image credit: Alexander Kvashnin, Skoltech)

Diamond is one of the only adequately hard and tough materials for the task of constant grinding without major wear, but as any imminent proposee is aware, diamonds are costly. High costs drive the hunt for novel hard and superhard materials. However, the experimental trial-and-error search is itself costly.

A basic and dependable method to predict new material properties is required to facilitate contemporary technology development. Russian theorists have published just such a predictive tool using a computational algorithm in the Journal of Applied Physics from AIP Publishing.

“Our study outlines a picture that can guide experimentalists, showing them the direction to search for new hard materials,” said the study’s first author Alexander Kvashnin, from the Skolkovo Institute of Science and Technology and Moscow Institute of Physics and Technology.

As fiber optics with its quick transmission rate substituted copper wire communications, so too do materials scientists hunt to locate new materials with desirable properties to assist modern technology.

When it comes to space, mining, and defense industries, it is all about identifying materials that do not break easily, and for that, the ideal combination of hardness and fracture toughness is necessary. But it is complicated to theoretically predict fracture toughness and hardness. Kvashnin explained that though many predictive models are available, he estimates they are 10%-15% off the mark at best.

The Russian team recently formulated a computational method that takes into consideration all possible combinations of elements in Dmitri Mendeleev’s periodic table—named “Mendelevian search.” They have applied their algorithm to hunt for ideal tough and hard materials.

By merging their toughness prediction model with two familiar models for material hardness, the researchers’ algorithm learned which regions of chemical space of compounds were highly promising for tough, hard phases that could be synthesized without any trouble.

Results were marked on a “treasure map” of toughness vs. hardness, and the researchers were fascinated by what they saw. All well-known hard materials were predicted with over 90% accuracy. This substantiated the search’s predictive power, and the newly exposed combinations are potential treasures for industry.

Kvashnin explained he is part of an industrial project dedicated to new materials for drilling bits, where experimentalists are currently synthesizing one of these valuable hard materials—tungsten pentaboride (WB5).

This computational search is a potential way to optimize the search for new materials, much cheaper, faster and quite accurately.

Alexander Kvashnin, Study’s First Author, Skolkovo Institute of Science and Technology and Moscow Institute of Physics and Technology

Kvashnin anticipates that this new method will allow the quick development of new materials with improved properties. However, they will not be stopping just with the theory. They want to apply their modern techniques and approaches to determine the basic rules for what makes hard and superhard materials among the elements, thereby properly guiding scientists of the future.