Milacron will be displaying its industry-leading engineered technologies at K 2019 with key focus on eco-friendly machine designs offering innovative energy savings solutions, including injection molding machines, Mold-Masters hot runners and industrial supplies amongst others.

Milacron’s Products Highlights at K 2019

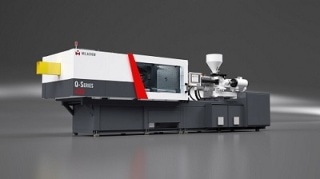

Q-Series

The Q-Series is a culmination of efficiency, consistency, and globally engineered technology. The Q-Series is part of Milacron’s Quick delivery lineup, allowing the machines to be built and delivered to a manufacturing facility quickly. Leveraging the use of a servo motor in combination with hydraulic components, Q-Series provides exceptional repeatability and energy savings. The eco-friendly design generates savings in electrical power consumption, cooling requirements, and lower maintenance cost.

Milacron will be displaying its industry-leading engineered technologies at K 2019 with key focus on eco-friendly machine designs offering innovative energy savings solutions, including injection molding machines, Mold-Masters hot runners, industrial supplies and others.

Elektron

Elektron from Milacron provides clean, precise, efficient production in a full range of applications. It uses 60% less energy and 90% less water than hydraulic injection molding machines, reducing operating costs substantially. The engineered parallel movements paired with the servo-driven axes make the Elektron ideal for the reliable production of high-precision parts with fast repeatable movements.

MPs

The Maxima Performance Series addresses the market demand for higher performance, precision, and flexibility. This platform delivers faster cycle times, wider platens; a precision greaseless clamp guided on linear bearings, and integrated auxiliary capability.

Maxima Servo is one of Milacron’s most energy-efficient machines. The servo-hydraulic machine provides up to 70% energy savings over similar machines, with a reduction in molding costs, maintenance costs, and heat load on the factory floor.

Cincinnati – CE

The Cincinnati is a NEW large tonnage, true two-platen machine designed to meet the demands of the global automotive, appliance, and other large part molding markets. The Cincinnati’s enhanced machine specifications and performance are powered by proven Fanuc servo motor power packs for improved reliability, higher max mold weights, faster clamp speeds, and added tonnage sizes.

M-Powered

M-Powered provides a competitive advantage by increasing machine efficiency, reducing unplanned downtime, and improving quality. Leveraging the latest in Industrial Internet of Things (IoT) and data science, M-Powered provides unique insights and intelligence into your machine’s operations. The M-Powered connect portal puts key intelligence at your fingertips – in real-time, anywhere – be it in the office, through your (smart)phone, or tablet computer.

iMFLUX

Using iMFLUX, molders can increase productivity by up to 50% on existing injection molding machines. The process is ideal for most molding applications, but is especially advantageous for wide specification materials, recycled materials, and can help a biomaterial work for many more applications.

Extrusion – Twins, Screws & Barrels

Milacron extrusion solutions involve advanced manufacturing technologies that lead to improved product quality, reduced delivery lead time, and improved customer field service support.

ServTek

Milacron ServTek works to bring the industry’s most extensive line-up of services and tools to help you get the most from your plastics processing machinery. From price matched parts, machinery service, and consultation, to rebuilding/repurposing of older plastics machinery, Milacron ServTek provides with the widest range of tools and resources required to improve your processes and your bottom line.

Mold-Masters

Mold-Masters SeVG+ is a servo-driven system that provides absolute control and precision over individual valve pin opening and closing actuation profiles. Each SeVG+ system includes an SeVG+ controller, which features a large, easy-to-use touch screen display, on-the-fly adjustments, compact cabinet dimensions, and available TempMaster hot runner temperature control integration.

DME XPress™ – Any Shape, Any Steel program

DME introduces enhancement to its XPress™ mold base range, by adding 25 additional steel grades, all European certified through its “Any Shape, Any Steel” program.

DME CoolingCare – Reduced Cycle time/Improved Mold Productivity

DME CoolingCare is the new automatic device for cleaning, diagnostics, and maintenance of mold cooling channels. It provides the first ever Industry 4.0 capability with built-in modem for online diagnostics and service, a dedicated application for mobile devices allowing for the online monitoring of the cleaning process, report database, and automatic adjustment system.

K Show will take place from October 16-23 in Dusseldorf, Germany, and Milacron is in Hall 1 Booth C05.