Forge Nano, a global leader in surface engineering using precision nano-coatings via atomic layer deposition (ALD) for industrial powders, flats and objects, today announced that it has selected the Voltaiq Battery Intelligence platform to provide comprehensive battery data analytics to further enhance its next-generation battery coating technology.

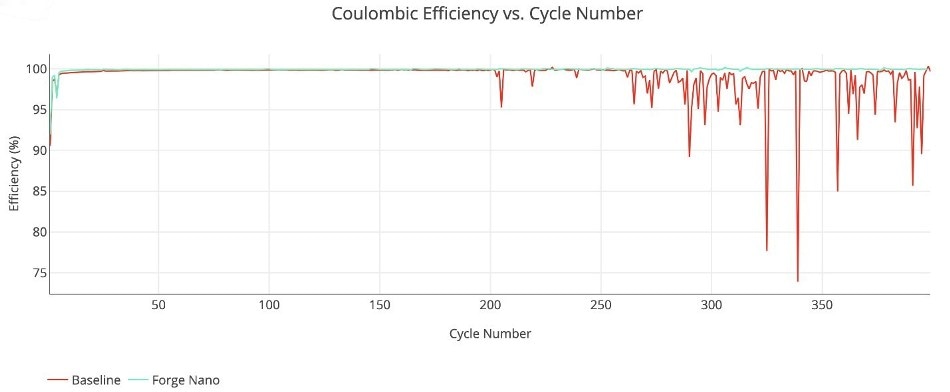

This plot created in the Voltaiq platform shows that the batteries made with ALD-coated materials have fewer irreversible reactions as compared to the baseline material.

This plot created in the Voltaiq platform shows that the batteries made with ALD-coated materials have fewer irreversible reactions as compared to the baseline material.

"The Voltaiq battery analytics platform has allowed Forge Nano to garner fast and in-depth analysis of our ALD-enhanced battery materials, expediting product development and ensuring timely execution of customer deliverables," said Dr. Barbara Hughes, Forge Nano's Director of Energy Storage.

Forge Nano's Atomic Layer Deposition battery coatings have been proven to improve battery performance significantly by creating a core-shell structure to protect particles of active material, which can prevent degradation, allow operation at higher voltages, increase electrode capacity, improve cycle life, enable faster charging, improve safety, and tune interfaces between different materials.

"Forge Nano is a leader in battery materials processing, and we excited they are using our Battery Intelligence platform to improve their coating development process," said Tal Sholklapper, cofounder and CEO of Voltaiq. "Forge Nano's ALD coating on battery materials already improve the performance of batteries in terms of cycle life, power, and energy density, and we believe comprehensive analytics will provide helpful insights to further enhance the technology."

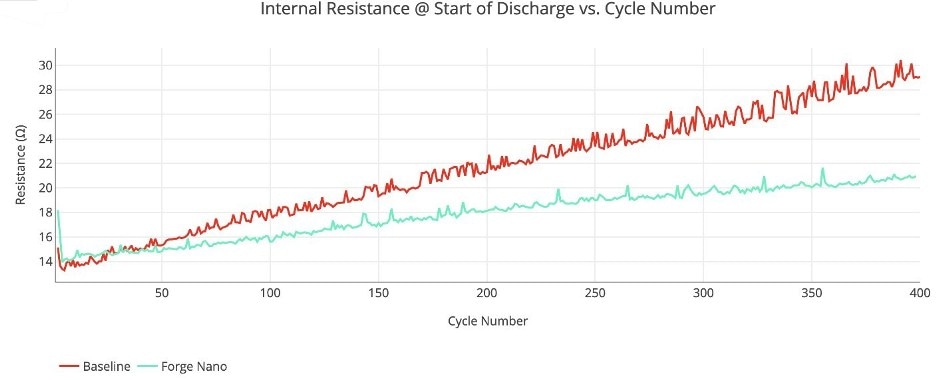

This plot created in the Voltaiq platform shows that batteries made with Forge Nano's ALD-coated materials maintain a lower internal resistance compared to the baseline material, meaning one can get more power from the battery.