At K 2019, Total Corbion PLA (hall 6 / booth E23) will highlight its Luminy® Poly Lactic Acid (PLA) portfolio and the most recent application innovations. The company will be co-exhibiting together with parent company Total.

The Luminy® PLA portfolio includes both high heat and standard grades and is used in a wide range of markets, from packaging to durable consumer goods and electronics.

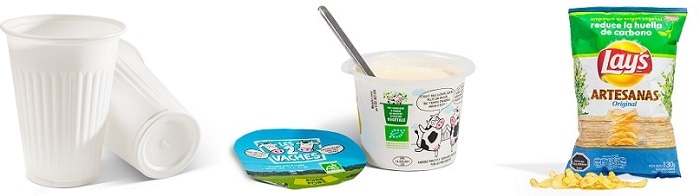

At K 2019, Total Corbion PLA will be showcasing several partner applications based on PLA to illustrate the range of possibilities offered by this versatile biopolymer.

High Heat Capabilities of PLA on Display

Pacovis’ naturesse product range exhibits the high heat capabilities of PLA through its PLA thermoformed cup. The cups are biobased, made from renewable materials and have a reduced carbon footprint compared to PS cups.

Another application includes PLA-lined paper cups, produced by EcNow Tech under their Earth Smart range Featuring a PLA lining that can withstand boiling water, they are a sustainable alternative to the traditional PE-lined variety based on oil-based plastics. The cups have a lower carbon footprint and can be industrially composted after use (where local facilities exist). Other high heat PLA applications on display at K 2019 include coffee capsules for Nespresso machines from ATI and tea bags from Nonwoven Network. Pepsico and Danimer have developed a compostable PLA/PHA-based potato chip packaging for the Chilean market. PLA/PHA-based drinking straws from Danimer are another innovation that help reduce the environmental impact of plastics.

PLA Applications for Food and Packaging Industry

Additional PLA innovations include:

- PLA-coated paper drinking straws from Shanghai Xinxin

- PLA single use shot glasses by Propac.

- A ‘slate-look’ bioplastic thermoformed black platter for attractive presentation of foods such as cheese, sushi and finger food by Pack & Proper

- PLA pots from organic yoghurt brand Les 2 Vaches (Danone), which replace traditional PS yoghurt pots

- A thermoformed food tray from Cuki Professional.

- Biobased and industrially compostable PLA trays for strawberries by S&A Group and Voges, and

- Compostable PLA breakfast cereal packaging by TIPA in the Netherlands

Durable innovations include:

- PLA-based butterfly feeders from ABM and Belightful Design

- PLA bottle openers from ABM

- PLA-based cosmetics jars by Berry Bramlage

- PLA computer mouse by Nager-IT and PLA rulers by Pratel in Italy.

Other examples of PLA applications include single-use PLA aprons from Gaia, foamed ice cream packaging from Synprodo, compostable PLA food packaging from Bio4Pack, PLA non-woven applications from Yangtze and PLA toothbrushes from PolyAlloy.

Make the Switch to PLA Bioplastics

PLA resins are made from annually renewable resources and are 100% biobased according to EN16785-1, offering a reduced carbon footprint versus many traditional plastics. At the end of its useful life, PLA products can be mechanically or chemically recycled. PLA is also compostable according to EN13432.

Responsible use of resources is of extreme importance to Total Corbion PLA and this includes optimal end-of-life solutions for PLA applications. The company is active in several mechanical and chemical recycling projects, including the re-CUP project where, together with Danone, CITEO, Looplife, Veolia and a few other parties, Total Corbion PLA is exploring the options for collecting and recycling PLA yoghurt cups on the French market.

Technical experts will be available at K show on the Total Corbion PLA booth for converters and brand owners to discuss the most sustainable end-of-life scenario for their PLA application.