Colloids Group is exhibiting with parent company, TOSAF Group Ltd. (Booth# Hall 8a / D01) at the K 2019 Plastics & Rubber exhibition in Dusseldorf, Germany, which runs from 16-23 October 2019. Colloids and Tosaf are global market leading manufacturers of masterbatches, compounds, and performance enhancing additives.

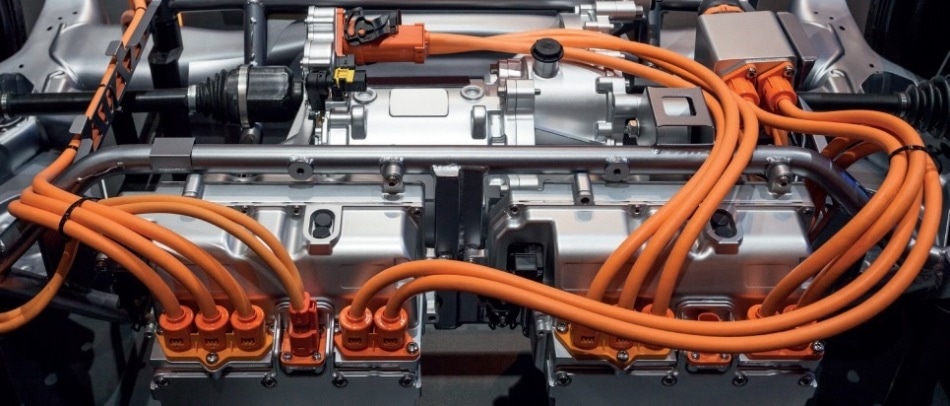

Signal Warning Orange (RAL 2003) masterbatch for high voltage electrical component applications for electric and hybrid vehicle engines. [Stock photo courtesy of Colloids]

Signal Warning Orange (RAL 2003) masterbatch for high voltage electrical component applications for electric and hybrid vehicle engines. [Stock photo courtesy of Colloids]

K 2019 is the ideal show for Colloids to showcase its latest specialty masterbatch products and to officially launch its expanded range of T-TEC® high performance polymer masterbatches. New T-TEC grades are now availability in Signal Warning Orange (RAL 2003) for producing high voltage (HV) automotive components; key applications include under the bonnet electrical components, conduits and charging plug units for electric vehicles and hybrids.

Show visitors to the Tosaf Group stand will be able to meet with commercial and technical people from the Colloids’ team and find out more about all the latest in-house R & D product innovations:

T-TEC High Performance Engineering Polymer Masterbatches and Compounds

Colloids’ T-TEC high performance masterbatches and compounds are formulated using specially selected high temperature pigments and engineering polymer carrier systems based on PPS, PPSU, PPA and PEEK. T-TEC masterbatches can withstand continuous operating temperatures in excess of 120oC and multiple heat histories at temperatures above 350 oC. Depending on the polymer grade, Colloids will supply a high-temperature masterbatch in standard blue, red, green, orange, brown, grey and black, as well as customer bespoke colours and formulations.

The newly expanded T-TEC range is now available in Signal Warning Orange (RAL 2003) for PEEK, PPSU, PSU, PEI, PA10T, PA12, PBT, PA6T and PA66 engineering polymers. This latest product development is primarily to offer car makers masterbatch grade options for producing high voltage (HV) automotive components, as Signal Warning Orange is the regulation colour specified by OEMs for high voltage cable and connector applications in a battery-electric vehicle (BEV), hybrid (HEV) and plug-in hybrid electric vehicle (PHEV).

The complete T-TEC masterbatch range has over 30 grades, based on a proprietary universal carrier as well as polymer specific grades, available in black and RAL/Pantone colours. Automotive, electrical and electronics (E&E), industrial and medical equipment are key application markets.

New Low VOC Black Masterbatch for Automotive Interior PP Foams

Polypropylene (PP) foams used in automotive interiors must meet stringent volatile organic compound (VOC) emission requirements to minimize fogging and odour levels in new vehicles. Colloids new low VOC black masterbatch has been tested according to VDA 278 for automotive materials and meets leading global automakers’ emissions criteria for volatiles.

New Permanent Laser Marking Compatible Masterbatch Range for Plastics

Colloids’ L-TEC® laser marking compatible masterbatch range enables plastic components to be permanently laser marked or etched with key product information and branding in either a light or dark mark instead of ink printing or engraving; text, numbers, QR and bar codes, images and logos can be clearly laser marked on a plastic part. The L-TEC laser marking range is available for a wide range of polymers in virtually any colour or effect, including metallic and pearlescent. Genuine automotive plastic parts can be permanently marked to protect against counterfeiting. Consumer products packaging, such as for food, drinks and cosmetics, also benefit from laser marking to add branding and aesthetic enhancements.

High UV Black Masterbatch for Exposed PE Agricultural Irrigation Drip Systems

Colloids has added a high UV protection black masterbatch to the range for the high speed extrusion of black polyethylene (PE) products that need to cope with prolonged exposure to direct sunlight. This innovative UV black masterbatch product was developed by Colloids’ R & D team in response to demand from leading manufacturers of overground ‘drip design’ pipe, tape and lay-flat tubing crop irrigation systems for the agricultural market. To maximize processing and UV resistance performance, the formulation combines optimized carrier and anti-oxidant systems with a high quality carbon black pigment.

The major competitive advantage for drip irrigation producers using Colloids’ PE compatible UV black masterbatch is that they can offer their customers a cost effectively produced drip irrigation system that is expected to last a minimum of two growing seasons in a temperate climate.

Colloids ‘Smooth’ Special Effect Colour Masterbatches

In response to market demand from producers of consumer goods and packaging, Colloids expanded its ‘bespoke’ special effect colour service offering. Colloids can now produce to order metallic, pearlescent, glitter, speckled, marble effects and fluorescent special effect masterbatch options. To meet the highest aesthetics and quality standards, Colloids ‘Smooth’ masterbatches are supplied to order for special effect colours; custom made ‘smooth’ masterbatch grades have proved to significantly reduce quality issues such as ‘die drool’ and extrusion ‘drag lines’, particularly with pearlescent colours. This enabling the production of high quality parts with a superior surface finish in shorter cycle times, so also improving productivity.

All products developed by Colloids provide added value processing benefits, such as higher throughput rates, along with improved quality and functional performance. As well as automotive, medical, industrial and E&E, Colloids products are also used in a wide range of plastic applications in agricultural, construction, pipes, geosynthetics, consumer goods and packaging markets.

Colloids Group manufacturing sites operate to ISO 9001 quality standards, with the main UK site at Knowsley also being ISO 14001 accredited. Both Colloids Knowsley and Colloids China are IATF 16949:2016 automotive quality management certified.