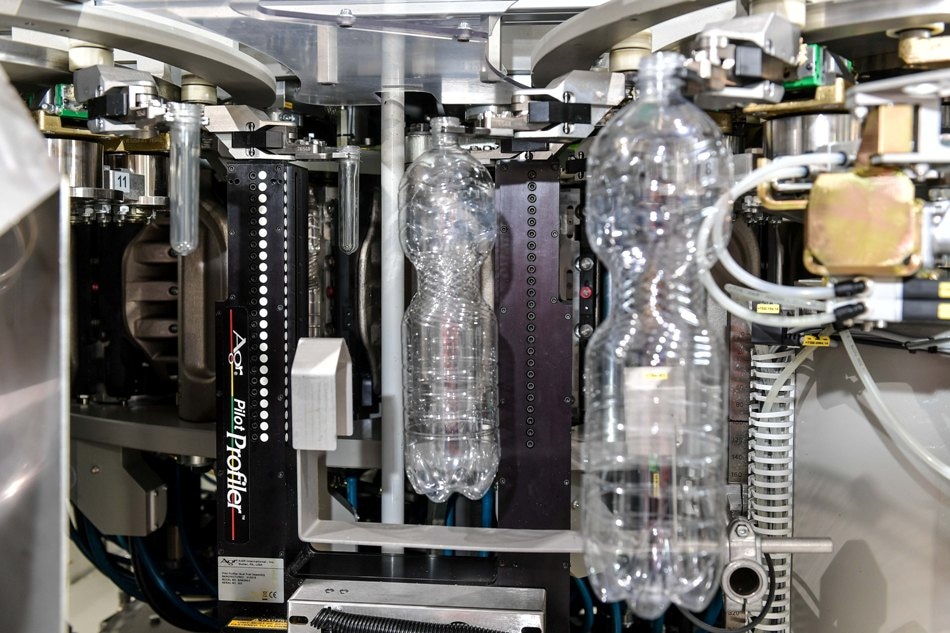

Even on the most advanced machine there can be discrepancies in the distribution of PET bottle material in the stretch blow molding process. This has an impact on the bottle quality and production efficiency.

(Source: KHS Group)

(Source: KHS Group)

In order to optimize these parameters KHS recently developed Unit Mold Control in cooperation with US company Agr International inc. (Agr). This digital, automated process control system, connected with the KHS controller, now individually regulates the respective blow stations in KHS’ InnoPET Blomax series, thus minimizing any fluctuations in quality during stretch blow molding. This results in improved bottle stability coupled with lower preform weights. This had proved something of a challenge to date, especially where containers with a high recycled PET content are used.

On a stretch blow molder the amount of wear on the individual blow valves used can vary. This means that the bottles blown with the same also change throughout the service life of the stretch blow molder depending on the station used. In the production process this can cause discrepancies in the distribution of material and thus to differing thicknesses of bottle wall. To date parameters could only be adjusted for the entire machine and not for each individual station. With the new digital Unit Mold Control system manufacturers optimize their blow molding process by making individual settings for each station. “This enables material distribution to be more precisely controlled per station, thus minimizing variations in the wall thickness from mold to mold by more than 30%,” explains Frank Haesendonckx, head of Technology at KHS Corpoplast.

Unit Mold Control adjusts settings fully automatically

To this end, Unit Mold Control inspection technology constantly measures the material distribution in each bottle and adjusts the settings for optimization fully automatically. “With this system deviations in the individual mold stations are identified. By applying an algorithm the degree of variability is reduced without operator intervention and possible incorrect settings are avoided,” states Haesendonckx. Furthermore, the data captured from the individual mold stations provides valuable information for the condition-based maintenance of valves, stretching systems or mold shells, for instance.

Unit Mold Control yields further benefits with regard to the growing percentage of recyclate used in PET bottles in particular. “Process accuracy reaches its limits with containers such as these,” Haesendonckx says. “As the material quality varies when recycled PET is used, the bottle becomes less and less stable the less the preform weighs or manufacturers have to use heavier preforms to ensure stability.” With the new system weights can be reduced while retaining bottle stability, claims Haesendonckx. “Unit Mold Control effectively compensates for discrepancies by identifying any unwanted material displacement during wall thickness inspection and automatically counteracting this.”

Partner Agr is also convinced by the joint new development. “Our commitment to the global beverage market is to provide innovative process control solutions for the factory floor,” says Robert Cowden, COO of AGR. “In doing so we’re helping to constantly optimize processes and improve production line efficiency and productivity by reducing unplanned downtime, labor content per produced container and energy costs.”

Unit Mold Control is available as an option for KHS InnoPET Blomax Series IV and V stretch blow molders and has already successfully proved itself on the market several times over. Furthermore, the new system – whose industrial property rights are held by KHS and Agr – can also be retrofitted into existing plant machinery.