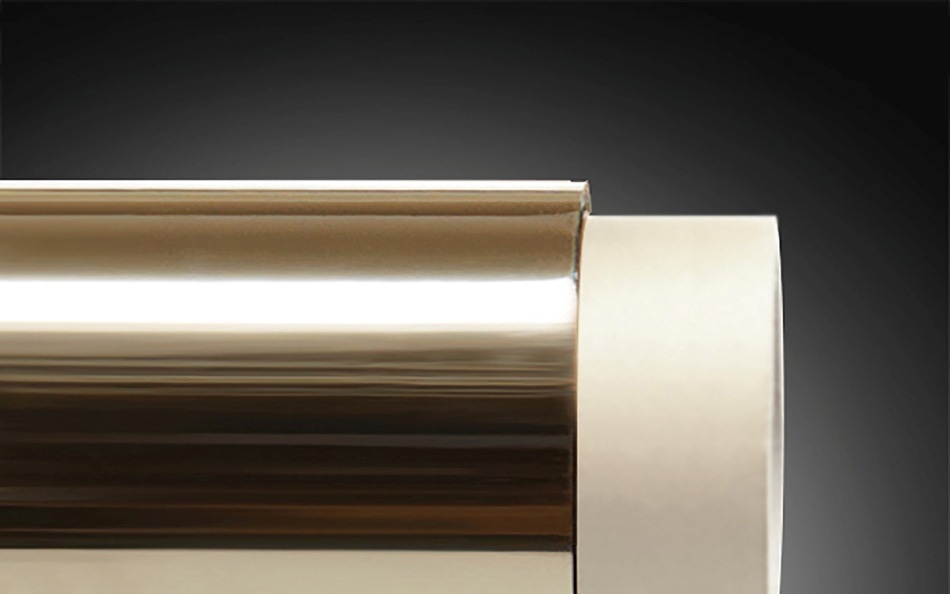

To help advance micro speakers in various types of mobile devices, including smartphones and headphones, Victrex has announced the launch of an ultrathin APTIV DBX film product line.

The new films´ tighter thickness tolerance is designed to result in a more uniform thickness to enable laminators, speaker builders and OEMs to improve consistency and yield – and consequently to help meet quality, reliability and performance requirements. The new film products based on high-performing PEEK polymer are available in thicknesses from 3 to 6 microns.

More and more people consume visual and audio media, such as videos, music and games on their smartphones and other mobile devices. In this highly competitive market, the electronics industry is challenged to produce improved micro speakers with higher quality and performance. In particular, they must support higher sound output and a broader range of frequencies for a louder and richer sound experience without compromising the functionality of the device. In micro speakers, diaphragms of only a few microns thick play a key role in delivering an excellent acoustic experience. However, even a minute variability in film and diaphragm thickness could cause defects in acoustic performance and reliability. Improved material quality and in-depth design and processing know-how are required among other things to avoid that.

“In my opinion tighter thickness tolerances will give a speaker builder not only better yield, but also the ability to sell products to top brands - and achieve a premium in the market,” said Guangbin Shi, currently Senior Audio Electrical Engineer, Hytera, and formerly Audio Engineer at ZTE, a major Chinese handset OEM.

Improved thickness management

With a thickness tolerance of +/-5%, Victrex’s new APTIV DBX film, optimized for micro speaker diaphragms, is expected to enable more uniform laminate thickness, resulting in greater part-to-part consistency. This should lead to lower F0 and THD variability, meaning more consistent acoustic performance. Generally, reducing the variance in film thickness can also help to increase yield, lower overall manufacturing costs by reducing scrap, and help to meet production ramps on schedule. In turn, laminators should be confident that winding and handling will be easier, while speaker builders will better be able to meet OEM specs and supply quality parts consistently. The OEMs themselves will experience a renewed confidence in meeting challenging market demands for superior speaker design, allowing them to deliver on their brand promise of seamless connectivity.

“To address changing market challenges, we continually focus on improving our product offerings; APTIV DBX film is clear proof of that,” commented Takaharu Kannari, Director Electronics at Victrex. “We’re convinced it can contribute to significant benefits, from the design to the manufacturing of micro speakers and headphones, including improved performance and reliability. We will continue to research and develop products that can help our customers to stay ahead of the game.”

APTIV film based on high performing PEEK polymer

APTIV film provides the benefits of high performing thermoplastic PEEK in a thin-film format and has been used for acoustic technology and components in more than 4 billion mobile devices. PEEK polymer is a member of the PAEK group of polymers and is regarded as one of the highest performing thermoplastics in the world. It is ideally suited to extreme and demanding environments. While alternative materials can meet specific needs, PEEK polymers support multiple requirements with their inert properties, which include lightweight and high strength, together with high resistance to wear, high temperatures, fatigue, and aggressive chemicals. Together, these contribute to extended part life.