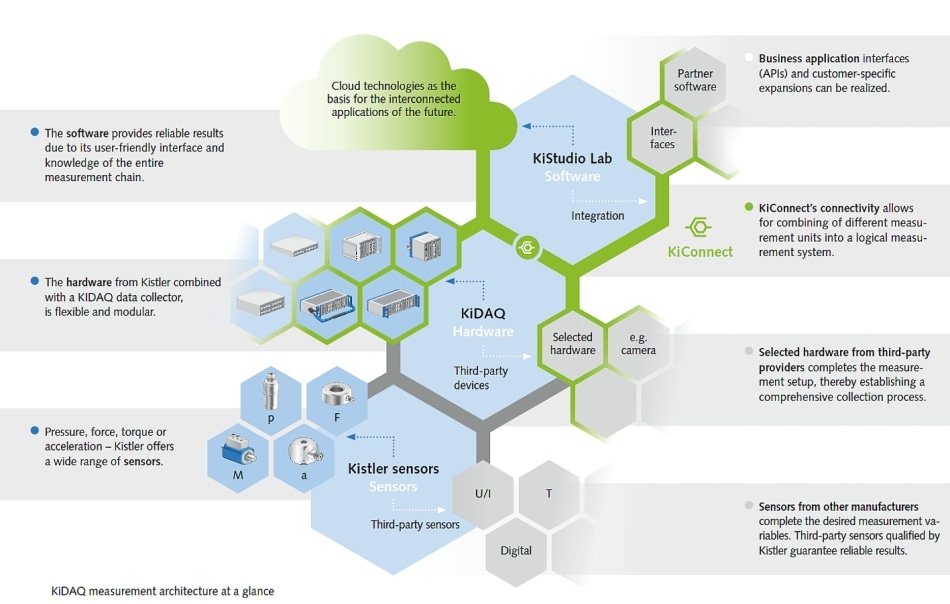

The modular design of the new KiDAQ from Kistler Instruments makes unlimited channels and distributed systems a reality whatever the application; industrial, laboratory, permanent installations and mobile. Engineers now have everything needed to complete any measuring task: a single integrated system that can be flexibly expanded at any time with additional measurement modules and units.

The new data acquisition system can be configured to suit any application with a choice of portable and 19 inch rack housings that can accommodate up to 13 measurement modules each, and DIN Rail modules for industrial installations with any number of measurement modules and other components of a system. This flexibility allows users to configure a data acquisition system that best meets to their current needs. Using components from Kistler’s hardware, software and sensor portfolios means that, as needs change, the original system can be adapted and extended by reconfiguring the existing modules and adding others as needed. Nothing is made redundant ensuring a low cost of ownership without compromising system performance and capability.

Reliable information about the measurement uncertainty

A key characteristic of the new KiDAQ data acquisition system is KiXact technology, which automatically calculates the measurement uncertainty. With know-how across the entire measuring chain, a reliable statement of measurement uncertainty is now possible with this technology. This eliminates the time and effort needed to manually calculate the measurement uncertainty of the whole system.

KiDAQ provides data transparency across the entire measuring chain. As Kistler qualifies the measuring components and calibrates them for each application, the exact specifications of their properties are available. The engineer is provided with precise details about their measurements and reliable information about measuring accuracy.

KiConnect technology: Nerve centre of the KiDAQ system

Drawing on smart KiConnect technology, users can put together various Kistler measuring components and, if necessary, add selected third-party devices to the system. The integrated Precision Time Protocol (PTP) ensures exact time synchronization between the devices in the local network. Based on standard protocols (TCP/IP) the measurements can be configured and performed anywhere.

KiStudio Lab software: The entire measuring task at a glance

The web-based KiStudio Lab software enables measuring tasks and projects to be easily processed and managed. The user interface is developed according to the latest usability criteria and designed so that it can be intuitively and efficiently operated by both occasional and experienced users. Via the software, engineers can access all measuring data and results at any time from current and older projects. The raw data are easily and securely stored in a central repository and can be exported in various formats and analysed offline. The stored measurement setup can be called up at any time in the case of further measurement tasks. This saves users the time required for complex test setup and measurements can be performed immediately the next time.