Due to increasing demand for lightweight construction materials for specialty applications, Evonik Corporation is expanding its production of ROHACELL® high performance rigid, closed-cell foams at its Mobile, Ala., site.

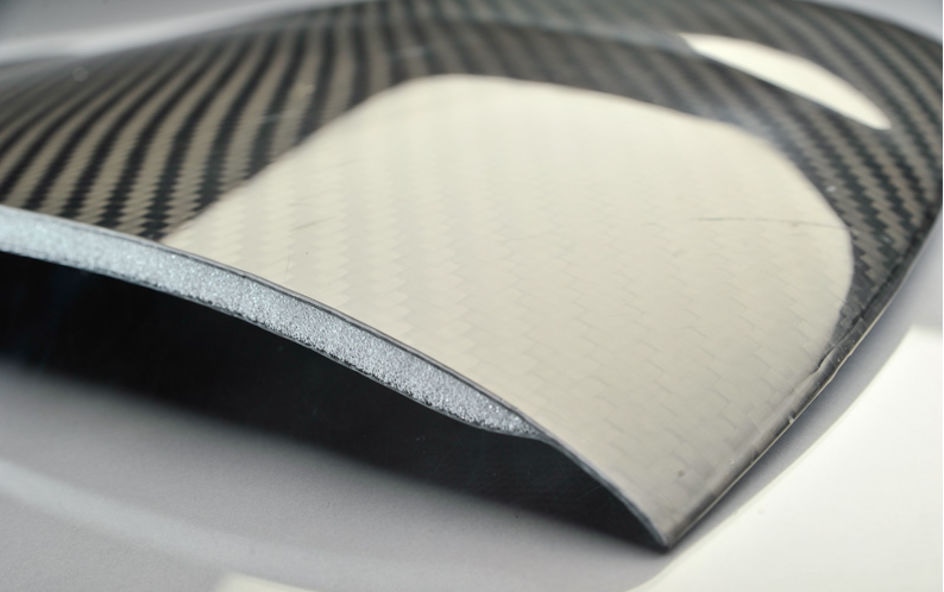

ROHACELL® foam forms the core of lightweight sandwich structures with high shear strength and compressive strength, even at relatively high temperatures.

ROHACELL® foam forms the core of lightweight sandwich structures with high shear strength and compressive strength, even at relatively high temperatures.

The production expansion is scheduled to be completed by the fourth quarter of 2020. With this investment, the specialty chemicals company will significantly increase production capacity for high-temperature resistant polymethacrylimide (PMI) foams in North America.

“The investment in Mobile strengthens our global position as a reliable partner and solutions provider of high performance, lightweight PMI-based rigid foams and enables us to meet increasing demand in North America over the long term,” says Christina Walkosak, head of the High Performance Polymers Business Line, Americas, for Evonik.

Lightweight construction material for specialty applications

The expansion of ROHACELL® production in Mobile includes the construction of an additional production hall. Moreover, all shipping logistics will be combined in the new facility.

It was in 2008 that Evonik ventured across the Atlantic to start production of ROHACELL® high-temperature resistant polymethacrylimide foams in Mobile.

“For many years now, we have been seeing consistently high global demand for our high performance foams, particularly from the aerospace industry and the electronics market, and we are responding to the marketplace by expanding our production capacity accordingly,” says Walkosak. Two years ago Evonik stepped up its ROHACELL® production in Germany by 20 percent. “Now we’ll be significantly increasing our output in North America to be able to support our customers’ growth appropriately.”

Core material solution for composite structures

ROHACELL®, a rigid structural foam of polymethacrylimide, is used in the design and production of sandwich structures in aviation, cars, ships, sporting goods, electronics, and medical technology. This extremely light foam withstands high temperatures and pressures, making it an ideal core material solution for composite structures. Such components can be produced quickly and efficiently, reducing production times and costs for the manufacturer. Additionally, the lightweight benefits of the product provide energy savings over the lifespan.