The Polyplastics Group has announced new developmental grades of LAPEROS® liquid crystal polymer (LCP) which offer superior blister resistance for electronic connectors. The two grades are currently in pre-commercialization phase and have been confirmed to inhibit blistering more effectively than existing materials and show strong potential for improving productivity. Polyplastics has conducted experimental studies on different forms of blistering and is working to achieve an even greater reduction in blistering defects.

Overcoming the Flaws with LAPEROS LCP

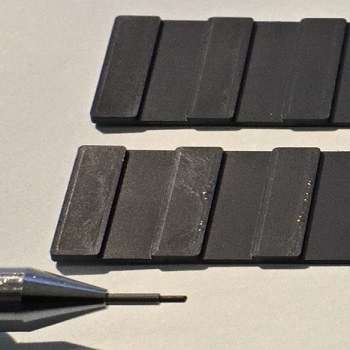

LCP is widely used in SMT (Surface Mount Technology) parts due to its strong heat resistance and flowability. Blistering is a common flaw for LCP which takes the form of bulges that appear on the surface of molded articles due to heat. Blistering has a variety of potential causes including LCP decomposition gases, gases that get entrapped during molding, and separation between the skin and core layers.

Higher Heat Stability

Polyplastics noted that it is important to use materials with higher heat stability and which also generate little gas. LAPEROS® LCP comes in a wide range of grades to accommodate customer needs, including ultra-high heat-resistant grades. The company has also conducted studies on nozzle and sprue optimization with the aim of offering solutions to blistering. Other factors such as molding conditions and mold shape design also have a strong influence on blistering.

Applications and Usage

In addition to high flowability and dimensional accuracy, LCP exhibits high heat resistance and is widely used in connector applications in devices such as smartphones which are becoming more compact and trending toward SMT. The automotive, home electronics, and office automation industries have also increasingly implemented LCP in recent years due to demand for high dimensional accuracy and heat resistance.