Graphi-Coattm 623, a new high temperature oxidation resistant coating developed by Aremco Products, Inc., is now used to protect graphite crucibles and fixtures used in metallurgical casting processes from the foundry to the jewelry industries to 2000 °F (1093 °C).

Features

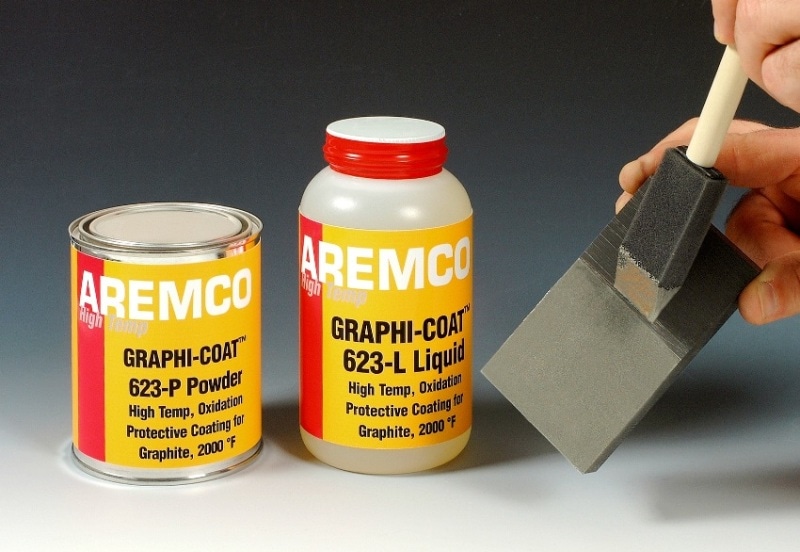

Graphi-Coattm 623 is a patented titanium diboride based coating that significantly inhibits the oxidation of most commercial grades of graphite to 2000 °F (1093 °C). This two-part system is a water-based, non-volatile material that is applied easily using a brush, roller, dip or spray process.

Graphi-Coattm is formulated with a weight and volume solids content of 78% and 58%, respectively. The coverage rate at a theoretical dry film thickness of 1 mil is 890 ft2/gal. A minimum dry film thickness of 2.5 mils is recommended. Once applied, Graphi-Coattm is typically air set for 1-2 hours at ambient temperature then cured in-situ or in 10-15 minutes at 1300 °F.

In addition to coating graphite crucibles and fixtures for metallurgical processing, Graphi-Coattm 623 can be used to protect graphite electrodes used in arc-melting furnaces.

Graphi-Coattm 623 is available from stock in pint, quart, gallon and five-gallon kits.